Many manufacturing companies are turning to custom electronic design services to help them develop products that are competitive in the market. A custom electronics design company can provide a variety of services, from product development and prototyping to circuit board design and PCB assembly. Here is why investing in custom electronic design is a smart move for any manufacturing company.

Why Custom Electronic Design Matters to Tech Companies

1. Time to Market – One of the most important factors in the success of a tech company is how quickly it can get new products to market. Being able to quickly and efficiently design and manufacture custom electronics is essential to success. A good custom electronic design partner will have a deep understanding of your company’s needs and be able to work with you to develop a product that meets those needs quickly and efficiently.

2. Cost – In today’s competitive landscape, the cost is always a factor. A good design partner will work with you to find ways to reduce costs without sacrificing quality or performance.

3. Quality – To be successful, your products must meet the highest standards for quality. Your design partner should have a proven track record of designing and manufacturing high-quality products that meet or exceed your expectations.

4. Flexibility – In today’s marketplace, things change quickly, and being able to adapt is essential to success. A good design partner will be able to work with you to make changes quickly and easily, ensuring that your products are always up-to-date and meet changing market needs.

5. Expertise – When it comes to custom electronics, you need a partner with the expertise necessary to get the job done right. Look for a company with extensive experience designing and manufacturing custom electronics for businesses like yours.

6. Customer Service – Last but not least, it’s important to find a company that offers outstanding customer service. You should feel confident that your questions will be answered promptly and that any issues will be resolved quickly and efficiently.

Increased demand for custom electronics

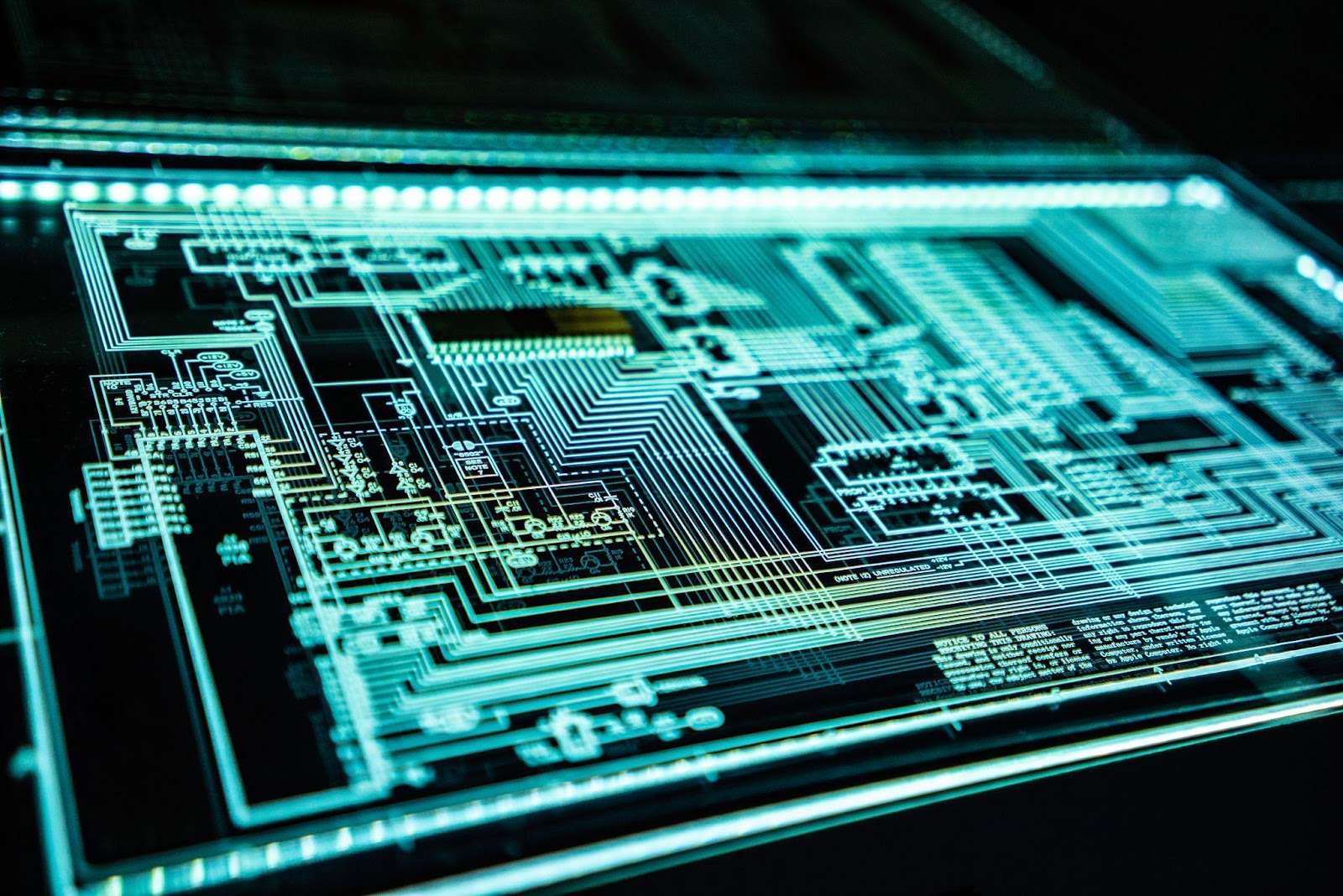

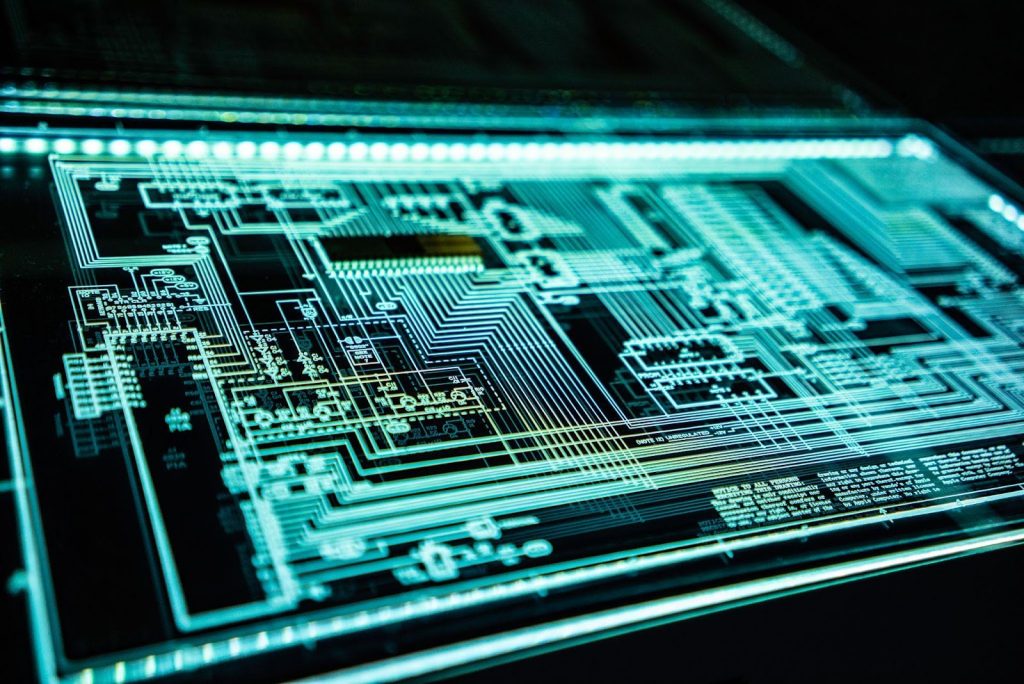

In recent years, there has been a growing demand for custom electronics, as manufacturing companies increasingly seek to differentiate their products from those of their competitors. This trend has created opportunities for designers, who can create unique circuit boards (PCBs) that meet the specific needs of their clients.

PCB design is a complex process that requires a deep understanding of electronic components and how they interact with one another. As a result, it is often necessary for designers to collaborate closely with their clients to ensure that the final product meets their expectations. However, the challenges associated with custom PCB design are more than offset by the potential rewards, both financial and otherwise. For those with the necessary skills and experience, custom electronics design offers an exciting and gratifying career.

How to get started with investing in custom electronic design

Powerful Functionality: With the custom electronic design, you are not limited to what is available on the market. You can create a product with all the features and functionality you need. In addition, a design can be used to create products that are not yet available on the market. This gives you a competitive advantage over other companies that have not invested in custom design.

Improved Efficiency: Custom-designed electronics can be created to be more efficient than those that are mass-produced. This is because they can be specifically tailored to your company’s needs. For example, if you have a manufacturing company, your custom-designed electronics can be created to streamline your production process. This will save you time and money in the long run.

Increased Durability: When you invest in custom electronic design, you can create a product that is built to last. This is because you can specify the materials and components that will be used in your product. This means that your product will not only last longer but will also be able to withstand more wear and tear.

The challenges of manufacturing custom electronics

One of the challenges faced by manufacturers is ensuring that the products they produce are of the highest quality. This means that they need to have a thorough understanding of the design and engineering process. They also need to be able to troubleshoot any problems that arise during production.

Another challenge faced by manufacturers is meeting customer expectations. This can be difficult when customers are expecting a product to be perfect. Oftentimes, customer expectations are unrealistic and cannot be met. This can lead to frustration on both the part of the customer and the manufacturer.

Lastly, manufacturers need to be able to scale their production to meet demands. This can be difficult if they do not have the necessary resources or if they are not able to keep up with changes in technology.

Benefits of investing in custom electronic design

1. Custom electronic design is important for manufacturing companies because it can help them save money and increase efficiency.

Design is important for manufacturing companies because it can help them save money and increase efficiency. Manufacturing companies often need custom electronics designed for their specific needs, and they usually turn to custom electronic designers to get the job done. They are experts at designing circuit boards, or PCBs, that meet the precise specifications of their clients.

By working with a designer, manufacturing companies can ensure that their PCBs are designed to their exact requirements, which can help to save money and increase efficiency. In addition, designers can also provide other services such as assembly and testing, which can further improve efficiency and reduce costs. As a result, manufacturing companies that invest in custom electronic design can enjoy significant benefits in terms of cost and efficiency.

2. By investing in custom electronic design, companies can reduce the number of prototypes they need to create and test.

For manufacturing companies, the design and development of new products can be a costly and time-consuming process. To bring a new product to market, companies traditionally have to create and test multiple prototypes, each of which can take months to produce.

However, by working with designers, companies can reduce the number of prototypes they need to create. By investing in custom design up front, companies can save time and money in the long run. In addition, custom designers can help companies to identify potential problems early on in the design process before prototypes are even created. As a result, custom design can be a worthwhile investment for manufacturing companies.

3. Custom electronic design can also help companies improve their production process and make their products more competitive in the market.

In today’s highly competitive market, manufacturing companies are always looking for ways to improve their production process and make their products more competitive. One way to do this is to use custom electronic design.

Custom electronic designers can help companies optimize their manufacturing process and develop new products that are more efficient and cost-effective. In addition, it can also help companies improve their production process and make their products more competitive in the market. By using custom electronic design, manufacturing companies can gain a significant advantage over their competitors.

4. Manufacturing companies that invest in custom electronic design will be able to stay competitive and succeed in the future.

As the world becomes increasingly digitized, manufacturing companies that don’t invest in design will be at a disadvantage. Those that do will be able to stay competitive and succeed in the future.

Custom electronic design can help manufacturing companies automate their processes, improve their products and increase their efficiency. It can also help them create new products and enter new markets. In a competitive market, manufacturing companies that don’t invest in design will be at a disadvantage. Those that do will be able to stay competitive and succeed in the future.

Conclusion:

Manufacturing companies need to invest in electronic design because it can help them save time and money. By working with a company specializing in electronics, manufacturers can get products to market faster and more efficiently. Additionally, it can help reduce manufacturing costs and improve product quality. Custom electronic design – could be the difference between success and failure for any business.