1. Industrial Dust Collector

The industrial dust collector is a kind of air pollution control equipment used in industrial or commercial places, which can meet the safety requirements of the workplace and the surrounding environment. An effective dust collection system removes potentially harmful dust and fumes from the manufacturing process or the air in the surrounding environment.Searose Dust Control Brisbane advise the equipment is designed to purify and filter harmful dust and fine particles in the working environment to maintain the quality of air.

Different types of dust collectors

The types of dust generated can differ by industry. In this case, industrial dust collector is designed to meet extraction requirement by each industry. Generally, dust collectors can be classified into five main types:·

- Filter cartridge dust collector·

- Wet scrubbers

- Inertial separators

- Electrostatic precipitators

- Unit collectors

Each of these dust collectors is specially designed for a particular use.

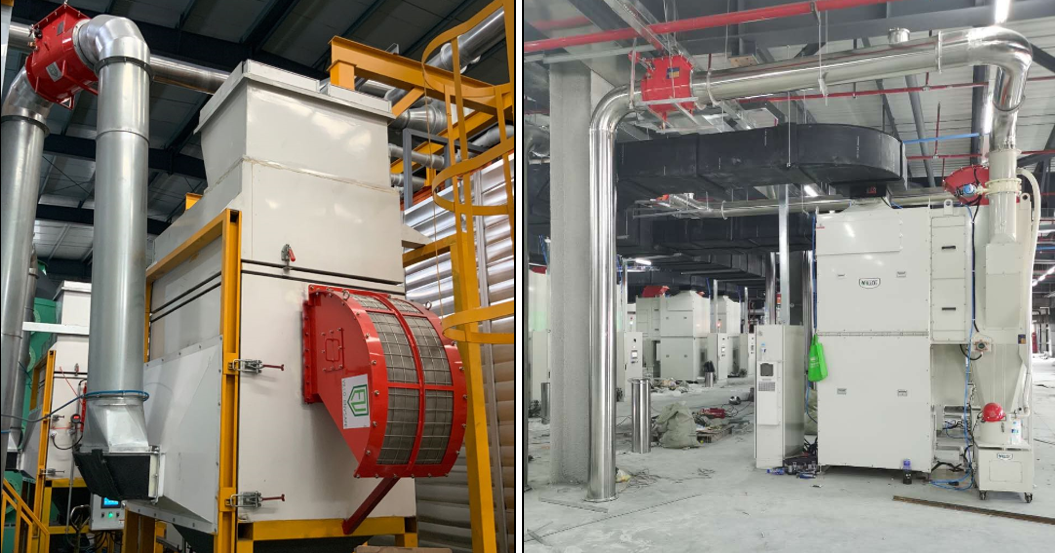

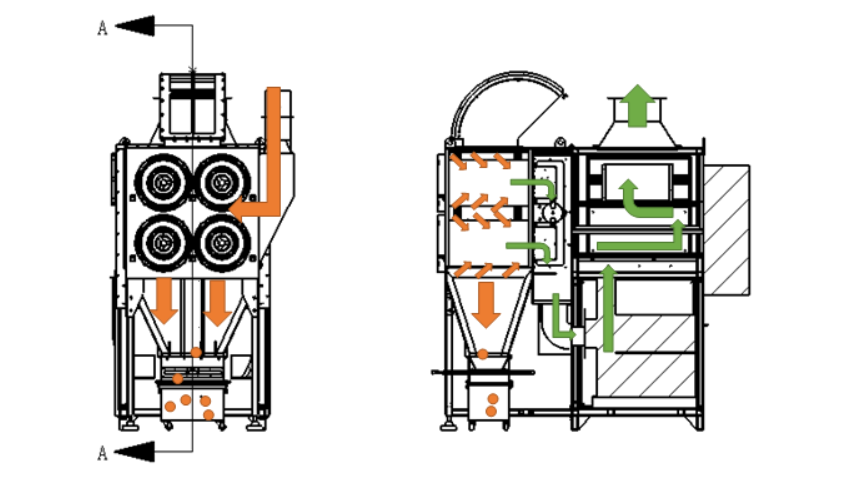

2. General Working Principle

The operating principle of the dust collection system is usually to absorb dust and particles from the air through a filter, and then discharge the clean air into the environment. When the dusty gas enters the dust collector through the pipe system, the airflow will be disturbed, then it will encounter the spoiler and slows down by encountering the spoiler. The coarse grain particles in the airflow settle down on the ash hopper under gravity, and dusty particles with fine granularity and low density enter the dust filter chamber through the integrated effect of Brown diffusion and percolation, dust deposits on the filter material’s surface. The depurative gas enters the chamber and is discharged by the fan’s exhaust pipe (as shown in the figure).

Most dust collectors come with ducting that is connected to the inlet of a collector, a filter unit to filter the dirty air, a blower system to create airflow through the piping system and the internal body of the dust collector, a cleaning system for the filter and a discharge system for collecting dust particles for waste or recycling purposes. These parts might rely on the application simplifying the vital components to dust collection.

In reality, safety is the most pressing issue your business faces. Implementing the right solutions today protects your employees, and your revenue, in the long run.

The potential for disruption to your operations is one of the biggest concerns to implementing safety solutions. However, if you can’t afford to slow down productivity, then you likely can’t afford the costs of compliance issues, workplace injuries, or downtime either. Method of machine guarding must be provided to protect operators, and other people in the machine area, from hazards associated with normal operations.

3. Choosing the Best Dust Collector

Adding a dust collector is a valuable investment that can be made to ensure health and safety in the work environment. The selection of a dust collector depends upon various factors. These factors include what types of dust need to be extracted, dust characteristics and the required power and suction capacity of dust collector, etc.

3.1 Types and Characteristics of Dust

It is significant to consider the type of dust that needs to be extracted before choosing an industrial dust collector. The type of dust depends upon the industry and its operations. For instance, dust produced in the woodworking industry is different from that produced in the metalworking industry. As a result, the dust characteristics are also different. As most woodworking dust is combustible, it is necessary to consider a dust collector with explosion-proof and flameless venting features. For fibrous or sticky dust may require special filters.

3.2 Size of Dust Particulates

The size and texture of dust particulates are important to consider before choosing the right industrial dust collector. It might need a cyclone or other device to remove the large chunks of abrasive material from the air stream. Similarly, particulates like weld fumes may need a fume extractor with a high filter efficiency.

3.3 Filter Size and Material

Dust particle size is another important factor that is worth considering. Particle size lower than 10 microns is considered extremely dangerous as it can penetrate easily and can cause significant hurt to the lungs and body. Dust size of 0.3 microns is considered the most penetrating particle size (MPPS). When purchasing an industrial dust collector, ensure that the industrial dust collector is equipped with a high-efficiency filter to filter down the desired dust particle size.

3.4 Air Flow (Air Volume)

Airflow is the industrial dust collector’s capability to transport the air containing dust, and it is measured in CFM or m3/hr. The dust collection system must be able to minimize the CFM of each machine to be connected. It is also important to consider that every foot of the pipe will add resistance to suction, so it is necessary to calculate the pressure loss between the industrial dust collector and the place where suction will occur.

3.5 Brand and Price

Although an industrial dust collector’s cost should not be a determining factor, it plays an important role. The price depends upon several factors, such as size and type of dust collector, dust collectors’ features, the brand of dust collector, and so on. It is recommended to choose an industrial dust collector from a well-known brand for an affordable price.

4. Conclusion

Industrial dust collectors are important tools for several industrial manufacturing operations. They are key for controlling the air quality and ensuring the health and safety of employees. Villo dust collector is the leading industrial dust collector for sale. Villo dust collector provides various industrial dust collection solutions for the past several years. Villo dust collector has professional capability to identify the problem, models your facility airflow, and allow the engineers to propose an ideal solution. In all these cases, satisfaction and performance are guaranteed.