One of the most exciting pieces of technology to commercialize over the past decade or so has been within 3D printing as it promises plenty of change in the future from sustainable building and manufacturing processes to a change in home hobbies including model making and the like – some of the most impressive projects in the world already exceed expectations such as those shown from Dubai 3D Printing projects as it leads the world for the industry, but there are plenty of exciting home projects emerging too. For those looking to get started with 3D printing, there are two fundamentals to understand, and could change the 3D printing experience too.

Subtractive printing –

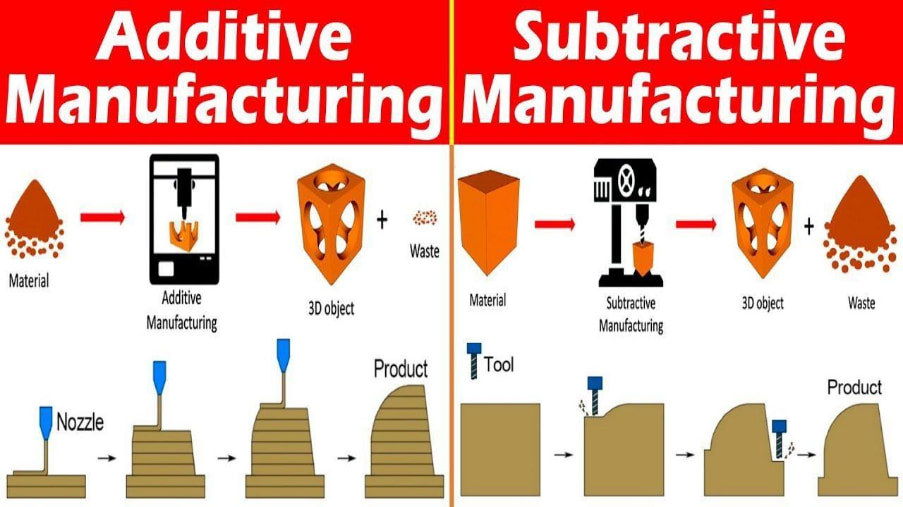

As the name would suggest, subtractive 3D printing is the act of removing material to create the end product, for older devices this may have been the act of starting with a larger block of material and working the plan around how to remove this material, similar to the way many CNC machines currently work – whilst many modern printers work on the additive process now, it is still a big part of the process as subtractive printing remains an important part of any larger project, and still plays a role in smaller scale printing too.

Additive printing –

This process is the opposite, instead working by building layers of material to reach the end product – this requires a larger spool of material that is gradually fed through, and the project is built this way. This can be a slow process for the larger projects, but has revolutionized the way some process take place, but the slower process can be fairly cheap with the energy cost being the defining factor for some instead which has helped change expectations for much larger projects too.

Both will still continue to be widely used throughout the manufacturing process for different purposes – finished products will often come from a subtractive approach whether through 3D printing machines or more likely through CNC options, particularly for higher volumes where speed is key, but more specialized parts that are required to save weight or have very intricate designs are better suited for additive manufacturing, and this is where 3D printing is really shining as speed isn’t necessarily a factor.

For those looking to take advantage of home style manufacturing, research both to see what process fits personal needs better whether a more expensive process is manageable, or if slow and steady is a better fit.