Wiring harness technology has evolved throughout the decades. Since fitting a good quality wiring harness has been proven to make the whole wiring system more efficient., it’s not surprising that they are utilized in numerous industries. A wiring harness also reduces the installation time of the entire wiring system in any device.

It allows the manufacturer to install the entire system as single electronic wiring instead of fixing the wires separately. Harnesses also protect the entire wiring system from external elements that could damage it. It reinforces the wires and protects them from vibration and moisture. It also reduces the risk of short circuits, since electronic cables are usually covered with damage retardant insulators.

The Early Days of Wiring Harnesses

Electronic wiring harnesses started becoming more popular in the 1920s when the automotive industry was still in its infancy. Engineers have discovered that by simply connecting wires and cables, they can strengthen the device’s entire wiring system.

With the development of the manufacturing industry, there was a need for a better way to handle complex wiring. Before that, mounting wires and cables were not as efficient and time-consuming with workers laboriously installing every component individually. Today, many industries rely on top-of-the-line wiring solutions to keep up with modern technological advancements.

Wiring Harnesses in Different Industries

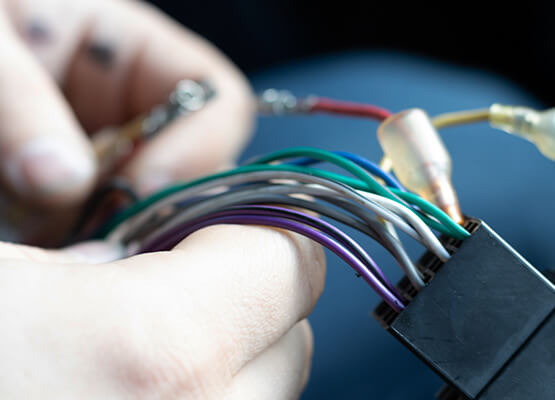

A common wire harness consists of wires, terminals, and connectors in a variety of shapes, colors, and sizes. The usual assembly method depends on the simplicity or complexity of the device. Complex electronic wiring may require a unique type of assembly. Wiring harnesses are essential in the manufacturing sector and are generally the backbone of many industries. They usually consist of several components, each of which is used in different ways to accomplish different tasks.

Manufacturing– The growth of the manufacturing industry can be attributed to the development of technology. Manufacturing is now more efficient with power tools and robots that streamline the manufacturing process. The use of wiring harnesses in many electronic machines and robots in factories has resulted in a more methodical manufacturing process. These harnesses control the entire technical system of the production line and eliminate the risk of errors.

Automotive– A wiring harness controls all the electrical functions of the vehicle from the dashboard to the lighting. Every operation of the vehicle requires a signal or transmission of energy from the wiring harness placed throughout the vehicle. Instead of having individual wires in different parts of the vehicle, it provides a better and more organized cabling system. The wiring harness protects and reinforces the hundreds or even thousands of components that make up the electrical system from external elements that can damage the entire vehicle.

Medicine– The development of medical technology has come a long way in history. Experts are constantly trying to find new and innovative ways to help people live better and longer. These medical discoveries would not have been possible without the use of efficient wiring harnesses. A wiring harness signals and transmits electricity to these machines, which should work without any possibility of error.