Over the years, technological advancements have led to the introduction of new materials to be used in various applications. Acrylic is one of the materials you can use in creating multiple items. It’s a homopolymer that’s commonly called “plexiglass.” Components such as acrylic acid make it impact-resistance. Read on to know some vital things about acrylic.

Acrylic’s History

Acrylic was developed in 1928 and sold after five years by Rohm and Haas Company. It’s one of the most transparent plastics on the market. That’s why it was used in making submarine periscopes and airplane windows in WWII. It was discovered that airmen injured by broken acrylic shards healed faster than those injured by shattered glass.

Modern Uses Of Acrylic

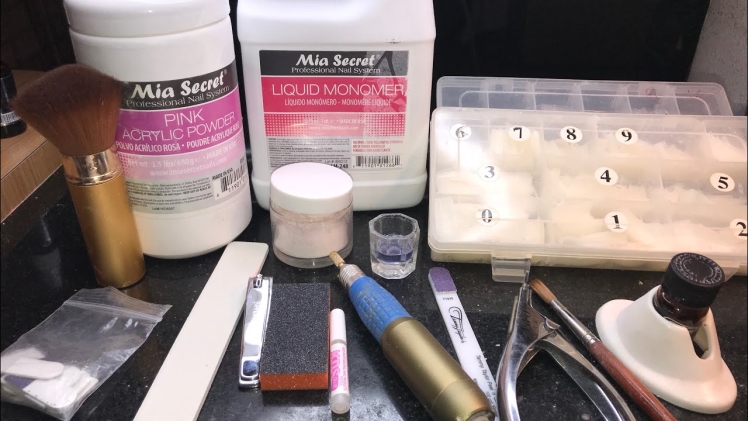

In this modern era, acrylic is used in various applications that require impact resistance and transparency. It’s used to create lenses, security barriers, LCD screens, nails, furniture, paint, and medical devices. Its clarity also makes it ideal in making enclosures around exhibits, windows, and tanks.

Acrylic can be found easily, and it’s cheap. You can use it to replace polycarbonate where material strength is not the main factor to consider. Furthermore, you can also laminate it on top of polycarbonate to reduce scratches on screens.

Features Of Acrylic

Acrylic has some key properties that make it suitable for various applications. Its thermoplastic property makes it difficult to melt under heat below 160ºC. Moreover, you can hit them to their melting point, cool them, and re-heat them again and they’ll not degrade. That makes them be easily recycled.

Why Acrylic Is Often Used In Applications

Though it is transparent and impact-resistant, industries prefer using it because it’s economical and a lighter alternative to glass. You can cut into very small pieces with fine shapes because it easily vaporizes when impacted with laser energy. However, its low strength and brittle failure may make it unsuitable for some applications.

Pros Of Acrylic

-

Excellent Transparency And Optical Clarity

Because of its superb transparency, acrylic gives an excellent light transmission and optical clarity. In fact, if properly polished, it can transmit up to 92% white light. That’s why it’s used in manufacturing lenses. Clear acrylic block is used for multiple purposes.

-

Impact Resistance

It’s estimated that it sheets may be seventeen times impact resistant than normal glass. Their resistance also makes them prevent component breakage. It’s a better choice for machining because it’s lighter than glass.

-

Temperature Resistant

This material can withstand different temperature variations, making it ideal for manufacturing medical manifolds. It’s also ideal for manufacturing microfluidic devices that require diffusion bonding and heat treatment. Additionally, its temperature tolerance makes it the best material to make food and beverage testing and analysis equipment.

-

Chemical Resistant

Most industries require equipment that’s chemical resistant. Though glass can offer such resistance, it’s delicate and quite expensive. Acrylic can be a better option to use in manufacturing chemical-resistant equipment for use in various applications. Microfluidics devices are an example of equipment that requires chemical resistance.

Conclusion

The invention of acrylics has made it possible for industries to manufacture devices that can be used in various applications. Because of its temperature, chemical, and impact resistance, it creates strong and durable tools. Its transparent property also makes it ideal for manufacturing equipment that requires light transmission.