Auger flights, the metal blades that help move grain and other materials through a machine, are an essential part of many industrial processes. They need to be tough and durable enough to stand up to constant wear and tear. But how are they made? This article takes you into the world where they’re manufactured. It’s a surprisingly complex process, but the end result is a vital component in machines all over the world.

What are auger flights and what do they do for a machine or process

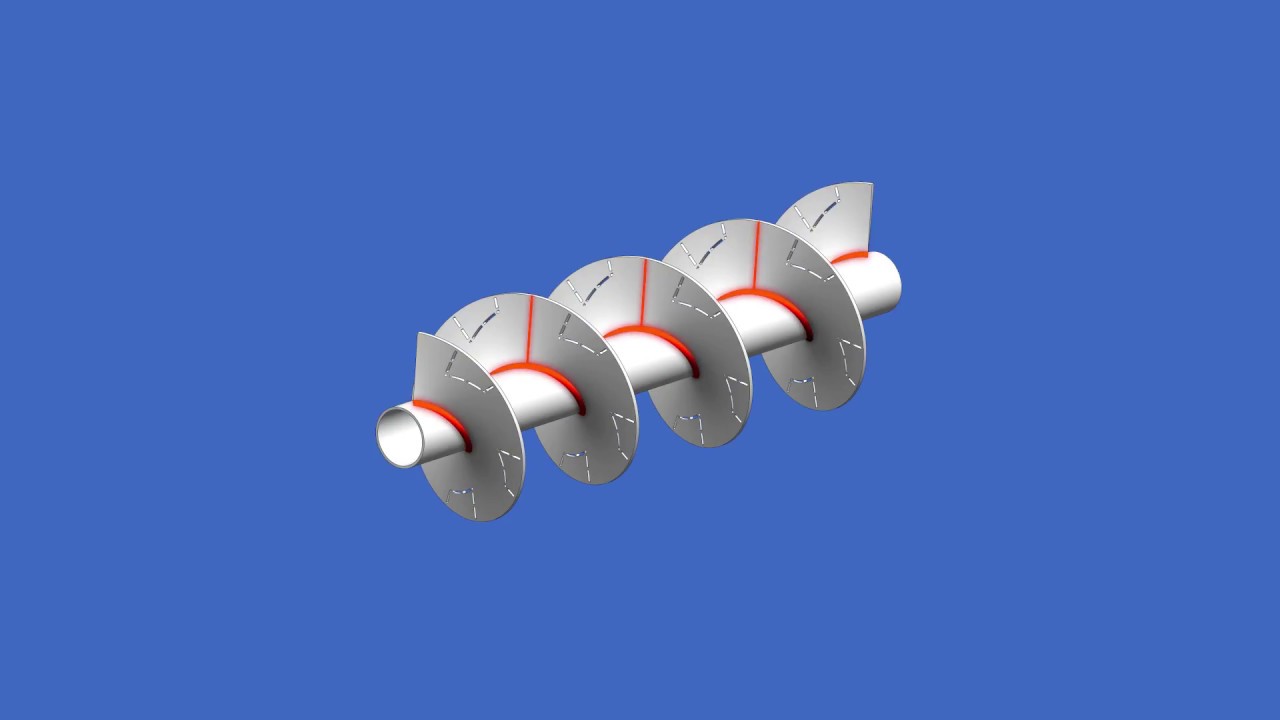

Auger flights are a type of screw conveyor used in many industrial applications. They are often used to move materials such as coal, grain, or price with a high degree of efficiency. The auger flight consists of a central shaft with spiral blades attached to it. As the shaft rotates, the blades lift and move the material through the conveyor.

Auger flights can be used in a wide variety of machines and processes, from simple agitated mixers to complex industrial dryers. In each case, they provide an efficient means of moving materials through the machine or process.

How is the shape of an auger flight determined and how is it made to be so sturdy and durable in order to resist wear and tear over time

The shape of an auger flight is determined by the application for which it will be used. The most common types are helicoid, sectional, and screw pitch flights. Helicoid flights are the most efficient at moving material, while pitch flights are the most common type used in agricultural applications.

Sectional flights are used when an auger must be able to navigate around objects in its path. The shape of the flight is also determined by the material from which it will be made. Auger flights are typically made from steel, but can also be made from stainless steel, aluminum, or other materials.

The material is chosen based on the durability requirements of the application. For example, stainless steel is often used in food-processing applications because it is easy to clean and resist corrosion.

Aluminum is often used in applications where weight is a concern, such as in handheld augers. The durability of an auger flight also depends on the manufacturing process. Auger flights are typically made by welding individual segments together to form a continuous spiral.

However, they can also be made by bending and welding a single piece of metal into a spiral shape. This method is typically used for small-diameter augers because it results in a stronger flight. Auger

In what ways can auger flights become damaged or worn down over time, and how can they be repaired or replaced

Over time, auger flights can become damaged or worn down in a number of ways. The most common cause of damage is wear and tear from regular use. This can cause the flights to become bent, cracked, or chipped.

In addition, they may also become corroded from exposure to moisture or chemicals. In some cases, the damage may be extensive enough that the flights need to be replaced. However, in many cases, it may be possible to repair the damage using a welding or fabrication process.

If the damage is not too severe, the flights can also be repaired by straightening them or by adding new sections of material. In some cases, it may also be possible to coat the flights with a corrosion-resistant coating to help extend their lifespan.

How do you know when it’s time to replace your old auger flights with new ones

As material handling equipment goes, screw augers are built to last. However, even the best-made auger will eventually need to have its flights replaced. Flight wear is caused by a number of factors, including abrasion, corrosion, and impact.

The good news is that there are several ways to tell when flight wear has reached the point where replacement is necessary. One key indicator is reduced capacity. If an auger that was once able to move a certain amount of material now struggles to achieve the same results, it’s likely that flight wear is to blame. Another telltale sign is increased vibration. Worn flights can cause the auger shaft to wobble, resulting in increased vibration levels. If you notice either of these signs, it’s time to consult with a screw auger manufacturer about replacing your flights. Doing so will help to ensure that your auger continues to operate at peak efficiency for years to come.