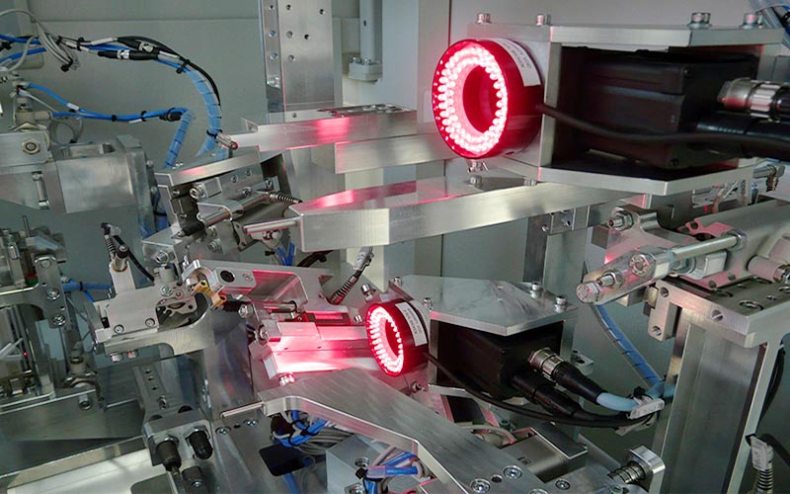

A vision system is a computer-based device that helps identify and classify objects in an industrial process. It does this by capturing images of the object and comparing them to data stored in the computer’s memory. If it detects an image that matches, then it sends out a signal which tells the machine what to do next. However, this article is all about how you can choose vision system inspection services for your business.

A typical vision inspection application might be for sorting objects such as nuts or bolts into separate bins according to size, length, weight etc. The operator identifies one type of bolt from another (for example) and sets up parameters for how they should be sorted (e.g., “all bolts longer than 20mm go into bin 1; all bolts less than 10mm go into bin 2”). The vision system then takes pictures of the bolts as they come down the production line and compares them to the set parameters. If a bolt is found to be too short or too long, it is diverted into the correct bin.

The benefits of using a vision system for inspection include:

- Improved accuracy and consistency

- Reduced manufacturing costs

- Increased throughput

- Reduced product damage

When looking for a vision system inspection service, there are a number of factors to consider:

1. Determine what you need:

The first step is to determine exactly what you need from a vision system inspection service. Do you need help with quality control? With product development? With sorting and packaging products? With problem solving? Once you know what you need, you can start looking for a service that can provide it.

2. Consider the size and complexity of your project:

The next step is to consider the size and complexity of your project. How many products do you need to be inspected? What are the dimensions and shapes of those products? Are they made from a variety of materials? The more complex your project, the more expertise and experience you will need from your vision system inspection service.

3. Look for experience and expertise:

When choosing a vision system inspection service, it is important to look for experience and expertise. A service that has been in business for many years will likely have the experience you need, and staff with the expertise to help you with your project.

4. Look for a partner, not just a service:

When choosing a vision system inspection service, consider whether you want to work with a “partner” or if you just want the service. If you are looking for someone to help find solutions and manage projects from start to finish, then look for a partner. If all you need is the service, then you may want to work with a provider that can supply the equipment and expertise, but leave it up to you to develop your own solutions.

5. Think about how flexible your service needs to be:

Vision inspection services are often complex and expensive pieces of equipment or software that need trained experts in order to use them. If this is the case, then you will need a service that can accommodate your specific needs.

6. Consider how fast and accurate inspection needs to be:

When choosing a vision system inspection service, consider how fast and accurate your inspections need to be. This will help determine the equipment requirements (i.e., camera speed etc.).

7. Consider the cost:

Of course, cost is always a factor when making any purchase. Make sure you ask the service how much it will cost to inspect your products and whether there are any associated fees (e.g., for training, set-up, or maintenance).

By following these steps, you can be sure to find the right vision system inspection service for your business.

Conclusion

In conclusion, a vision system inspection service can be a valuable asset for businesses of all sizes. By considering the factors listed above, you can find a service that will help you achieve your specific inspection goals.

Thank you for reading! For more information on vision system inspection services, please visit our website.

Recommended: Things to Know about Microcurrent Machines and How It works on Medical Spa