In the dynamic world of manufacturing and fabrication, where precision is paramount, grinding machines emerge as silent heroes, tirelessly shaping and refining materials to perfection. Let’s embark on a journey to unravel the intricacies of these indispensable tools and explore the diverse applications that make them the backbone of various industries.

Understanding the Essence of Grinding Machines

Grinding machines, at their core, are mechanical devices designed to remove excess material from workpieces, transforming rough surfaces into polished, precisely crafted components. The magic lies in their utilization of abrasive wheels or belts, meticulously grinding away imperfections to achieve the desired shape, finish, or dimensional accuracy. This process ensures that every manufactured part meets the stringent standards set by modern industries.

The Varied Landscape of Grinding Machines

1. Surface Grinding Machines:

- Ideal for flattening and smoothing surfaces, these machines employ abrasive wheels to deliver a flawless finish on materials such as metal, wood, or even composites.

2. Cylindrical Grinding Machines:

- Tailored for creating cylindrical shapes, these machines excel in achieving high-precision dimensions, making them pivotal in the production of shafts, rods, and other cylindrical components.

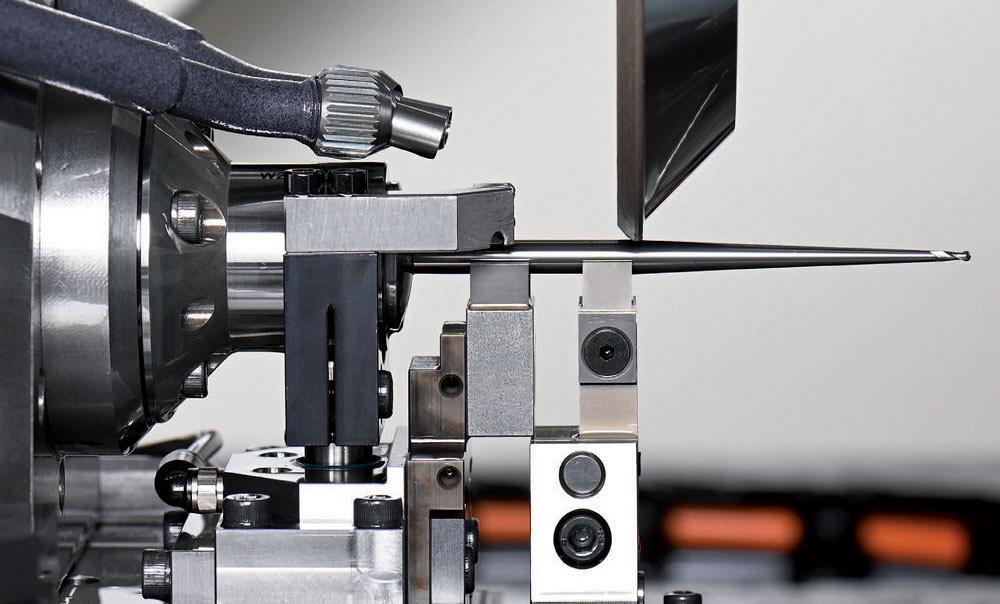

3. Tool and Cutter Grinding Machines:

- Essential for maintaining the sharpness of cutting tools, these machines play a crucial role in enhancing tool performance, contributing to the efficiency and longevity of tools used across various industries.

4. Centerless Grinding Machines:

- Revolutionizing outer diameter grinding, centerless machines eliminate the need for a centering mechanism, offering unparalleled precision for cylindrical workpieces.

Unveiling the Advantages of Grinding Machinery

1. Precision Redefined:

- Grinding machines are synonymous with precision, ensuring that manufactured parts meet the tightest tolerances and exhibit impeccable surface finishes.

2. Versatility Personified:

- From ferrous metals to exotic alloys, grinding machines exhibit remarkable versatility, capable of handling a diverse range of materials, making them indispensable across multiple industries.

3. Efficiency Amplified:

- In the era of automation, grinding machines have evolved to incorporate advanced features, reducing manual intervention, and maximizing efficiency in production processes.

4. Cost-Effective Manufacturing:

- The precision offered by grinding machines allows for material reuse by eliminating imperfections or excess material, contributing to cost savings and sustainable manufacturing practices.

Navigating the Future: Trends in Grinding Technology

1. Digital Integration and Industry 4.0:

- Grinding machines are embracing the digital revolution, integrating seamlessly with Industry 4.0 technologies. Real-time monitoring, data analytics, and predictive maintenance are becoming integral to the modern grinding landscape.

2. Sustainability at the Core:

- As environmental consciousness grows, manufacturers are adopting sustainable grinding practices, incorporating technologies that minimize waste and energy consumption, aligning with global efforts towards greener manufacturing.

In conclusion, grinding machines emerge not just as mechanical marvels but as crucial contributors to the precision and efficiency of modern manufacturing. As they continue to evolve with technological advancements, the future promises even greater levels of accuracy and sustainability, ensuring that the heartbeat of industries continues to pulse with unwavering precision.

Check out Sparx Machine Tools for more information.