Logistics is the process of transferring items along a company’s supply chain. It is critical for the supply chain’s efficiency and effectiveness that the many tasks associated with this process be met correctly. A well-managed supply chain visibility software benefits the bottom line, the pace of production, and the capacity to maintain track of inventories.

The worldwide logistics market was worth $9,525.1 billion in 2021, and it is anticipated to be worth $13,326.3 billion by 2027. It goes without saying that as transportation and technology improve, so will logistics. It is critical to comprehend how reasoning operates.

In logistics, there are both easy and difficult tasks. It is rarely simple to provide a service or product to someone. Logistics and supply chain visibility solutions are closely connected subjects. They collaborate to develop the optimal client-service logistical network topologies.

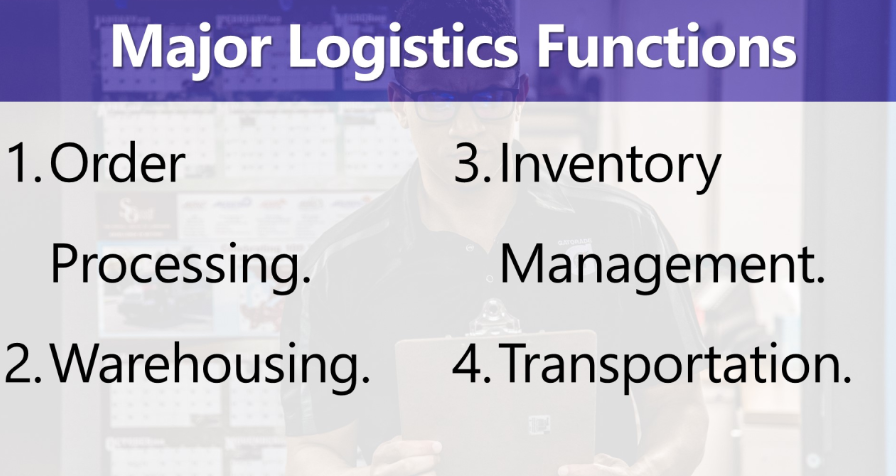

Distribution is only one aspect of logistics. It may be used for a variety of purposes. We’ll look at seven of the most essential logistics-related aspects in this post.

Processing Orders

If order processing failed, logistics would fall apart. Orders can be submitted through mail, phone, in person, or online. The orders must be filled as soon as possible. Order processing benefits both the organization and the client. Order processing consists of the following steps:

- checking to ensure that the contract’s conditions have not altered

- Spending Plans

- Stock-checking

When resources are few, production planning and acquiring new ones become critical.

Transportation

The logistics process in supply chain program is dependent on transportation to deliver items from the manufacturer to the consumer. Orders are not completed until the consumer receives the items. Transportation expenses can account for up to 70% of logistics costs for low-cost, commonly used commodities. Trucks, ships, trains, and planes may all transport freight.

When a corporation is deciding between multiple modes of transportation, the fact that some modes of transportation are only accessible in a specific state or region may play a role. When deciding on a mode of transportation, price is a significant consideration. Sometimes the customer’s requirement is more essential than the cost. The quickest option is always picked, regardless of cost.

Managing Inventory

Despite the importance of inventory management, the high cost of storage has a detrimental impact on income. It is critical to budget for inventory, security, storage, damage, repair, and theft. When managing inventory, it’s critical to strike a balance between what buyers demand and how much inventory should be on hand. It may be difficult to provide excellent service while keeping prices down and not losing market share.

Warehousing

It is critical for a company to have a location where finished goods may be stored until they are sent. The warehousing selections have an impact on how successfully the marketing works.

Modern data storage facilities are substantially larger than they used to be. Modern automation technologies have enabled one-story warehouses to take the role of multi-story complexes.

Storage is an important aspect of the logistics process. Modern warehouses reduce labor expenses and make inventory management considerably easier.

Packaging

Logistics real time transportation duties cannot be completed properly without the proper packaging. As a result, items have a more difficult time moving through the logistics chain. Packaging designed with marketing in mind is distinct.

When an object is packed, it is less likely to break, simpler to transport, and takes up less space. The cost of logistics packing is affected by how well a cargo is utilised.

Handling Materials and Storage

The way materials are handled has an impact on how well the distribution network functions. When consumers do not handle items gently, they break, delivery are delayed, and overhead prices rise.

Modernized manufacturing and material processing improve logistics. Consider how many items must be transported, how quickly they must be moved, and how effective the customer service is when selecting a material handling system.

The way a warehouse stores items has a significant impact on how efficiently it uses space. The supply chain system and the storage system must collaborate to make storing and retrieving items as quick and straightforward as feasible.

Monitoring

Businesses’ shipping, processing, and storage techniques are woefully out of date. Each location should consider its unique supply chain, commitments, and capacity to get additional supplies on a regular basis.

Before deciding on a distribution method, a company should consider the advantages and disadvantages of each. Keep track of when orders are placed, when they are completed, how much stock is available, and when they are sent. Businesses may become more efficient if they monitor their services and assess how well they are delivered.

The Role of Supply Chain Visibility Software in Logistic

Consider COVID-19 to understand why supply chain visibility is critical. This has an impact on enterprises of all sizes. As the holidays approach, prices for everything from Doritos to petrol to new houses rise, and retailers run out of stock, making it difficult for consumers to shop.

Couches and workout equipment are increasingly difficult to come by due to increased demand and erratic supply chain processes. The 5.4% year-over-year increase in consumer prices in the United States in September undoubtedly altered how individuals purchased goods.

Supply chain managers are in charge of allocating funds for essential items and resources and then rapidly replenishing them. The production line’s management need a snapshot of how the process is now unfolding.

According to expert, supply chain visibility is hampered by incompatible IT platforms. When information is locked in ERP or antiquated systems, it is difficult to manage supplier relationships effectively.

There are several advantages to seeing more of the supply chain network.

SCV systems display the amount of stock in the supply chain in real time. Stocking up on a regular basis has been proved to increase earnings and decrease losses.

Dashboards allow you to consolidate information from several sources into a single location, making it easier to administer a chain of enterprises. Automation can assist optimize the purchasing and shipping operations, reducing stock-outs and excess inventory.

Create Trust with Customers

If you are aware of how your supply chain companies functions, you might be able to give your clients better service while also making time and financial savings. It is better to apologize and explain the situation if a customer asks why their food took longer than expected than to just say, “I don’t know.”

Customers regard a company’s honesty highly. They ask questions regarding the procedures used in creating the items or rendering the services. Being more open might provide every business, from a software firm to a grocery store, a competitive advantage.

It is essential to comprehend where something originates from even if its precise origin or nature cannot be determined. Even while some customers think the differences between halal, kosher, and organic products are important, a blind test would show that the majority of people cannot tell the difference between the three product categories. Customers who appreciate ethics and authenticity are interested in a product’s origins.

The Impact of Disruptions Is Lessened

Pattern recognition, machine learning, and historical patterns may all be used to enhance future prediction. Real-time data might be useful in managing both predicted and unforeseen interruptions, such as problems with the supply chain and natural disasters. In order to change how stock is tracked and replenished and to address challenges, predictive analytics is being used. Logistical support services are also being used.

Technology for Tracking and Tracing

Globally, it is challenging to keep track of and be honest about things due to paper-based and disconnected data systems. Locating and identifying products may be made simpler by consumer-driven digital supply chain visibility tools. Using RFID, GPS, and EPOS technologies, anybody can track the journey of a product from its unprocessed parts to its final consumer.

Improve Communications

Keeping in touch with each supplier and stakeholder in a global types of supply chain software could be challenging. The delivery date can be postponed if one of your suppliers uses a third-party delivery provider and one of their trucks breaks down. To help keep things running as smoothly as possible in this case, SCV software may send out real-time messages.