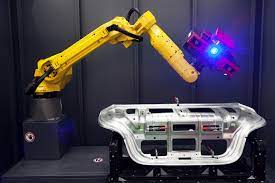

Automated industrial inspection systems are software and machines combo that is used to inspect the quality of products as they are manufactured. They typically use cameras or other sensors to scan the products for defects and then report any problems to the factory workers. This helps to ensure that the products are of high quality and meet all of the necessary specifications.

An automated industrial inspection system can provide numerous benefits for businesses, such as increased safety and efficiency, reduced costs, and improved quality. Here are five of the major benefits:

1. Increase Safety and Efficiency:

Automated industrial inspection systems (AIS) are increasingly being used to improve safety and efficiency in industrial settings. AIS can help identify and prevent hazards before they cause damage, which can save both time and money. In some cases, AIS can also improve the overall working environment by providing real-time information about conditions in a work area.

Automated industrial inspection systems can help to increase safety and efficiency in factories by identifying and correcting problems early. This can reduce the number of accidents, lower the cost of injuries, and improve workers’ productivity.

2. Reduce Costs:

Automated industrial inspection systems can reduce costs and improve the quality of products. These systems help identify potential problems early, allowing for corrective action to be taken before worse occurs. By reducing the time and effort needed for manual inspection, these systems can save businesses money in the long run.

Automated industrial inspection systems (AIS) reduce the costs of quality control, safety, and compliance inspections by automating repetitive tasks. These systems are becoming more prevalent in the manufacturing sector due to their ability to improve efficiency and accuracy.

3. Improve Quality Control:

Quality control is essential to the success of any manufacturing or assembly operation. Manual inspection is time-consuming and can be inaccurate, which can lead to product defects and even recalls. Automatic industrial inspection systems help ensure quality products by performing multiple checks on a production line in real-time and identifying potential problems.

They can also help identify problem areas earlier, saving time and money. Automated industrial inspection systems have become increasingly popular due to their efficiency and reliability. They are also becoming more affordable as technology advances.

Additionally, these systems can be customized to specific industries, making them more effective at detecting specific types of defects.

4. Increase Productivity:

Automated industrial inspection systems (AIS) are becoming more and more popular in today’s manufacturing industry. They can help increase productivity by streamlining the process of inspecting products for defects.

One of the main benefits of using an AIS system is that it can help to reduce the amount of time that it takes to conduct a quality check. This is especially important in industries where time is money, such as manufacturing.

Another benefit of using an AIS system is that it can help to reduce the amount of human error that occurs during inspections. This is because the system can automatically scan images and detect abnormalities on a large scale.

There are several different types of AIS systems available on the market today, each with its own set of advantages and disadvantages.

5. Lower Maintenance Costs:

Automated industrial inspection systems are a cost-effective way to maintain your factory. Using these systems can reduce the amount of time needed to inspect and maintain your equipment. This can save you money in the long run by reducing the need for repairs or replacements. Additionally, automated industrial inspection systems can help identify potential safety hazards early on, preventing accidents from occurring.

By automating the inspection process, businesses can reduce the need for human resources and free up time to focus on more important tasks.

Additionally, by identifying issues early, AISs can prevent costly repairs down the line. In fact, according to one study, AISs can save companies as much as 36% on maintenance costs.

Final Words:

Automated industrial inspection systems have many benefits that can help companies improve their operations. By using these systems, companies can improve their quality control, save time and money, and ensure the safety of their employees. Automated industrial inspection systems are a valuable tool for companies looking to improve their operations, and I encourage you to consider using them in your business.