Plastic is an affordable material used to make products for home, industry, business, or commercial use. It’s durable and long-lasting materials. It’s light-weighted yet strong enough to produce small to medium high-quality parts or components in large volumes.

Plastic is sustainable and can recycle after use. It can shape or reshape into any form. Everything we see today produces from plastic materials. This helps in reducing waste and keeps the earth green.

Understanding Plastic Tooling and Molds:

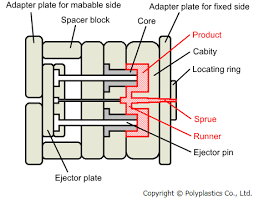

Plastic Injection molding is an effective process compared to others. When coming to plastic tooling and molds, it produces through the process of injection molding. The injection molding process starts with feeding plastic pellets into the hopper of the machine. Where plastic pellets get checked and verified for the final production.

Before jumping to start the process, a mold should consider first. A Mold helps the molten plastic liquid turns into uniform parts or products. A well-designed mold plays a great role in the manufacturing process. It shapes the uniform product and makes the entire manufacturing process cost-effective.

After the complete production run, the assembly services make the entire manufacturing process successful and cost-efficient. Injection molding involves taking the raw material and injects into a mold. The raw material melts into the heated barrel and injects into a mold for producing the final desired products.

Tooling is a significant step that involves mold, cast, fixing, and cutting equipment. It requires machinery and manufacturing components for production. Tooling affects the production speed, accuracy, and quality of the final finished parts or components.

The quality of tools and molds impact the quality of the final product. Further, it impacts the entire manufacturing process as well.

Advancements in Plastic Tooling and Molds:

It’s an innovative method in manufacturing for producing plastic parts and components with a good finish. It allows the use of 2d and 3d objects, to shape the molten liquid into different sizes and shapes.

3D printing and prototyping take place on the specification of the product. It helps in designing the objects/mold to shape the final finished product.

Plastic injection molding enables the production of custom prototypes and end-use products. It helps in producing complex parts with consultative design services. It has the ability to mold into different kinds of applications.

Conclusion:

Injection molding is the most usable method recognized all around the globe. It has unique features to make complex and accurate products using advanced technologies.