Thermal Relay Definition

The thermal relay consists of heating elements, a bimetallic sheet, contacts, and a set of transmission and adjustment mechanisms. The heating element is a resistance wire with a small resistance value, which is connected in series in the main circuit of the protected motor. The bimetallic sheet is formed by rolling two metal sheets with different thermal expansion coefficients. Thermal relays are often used in motors, other electrical equipment, as well as electrical lines. When the motor is overloaded, the current passing through the heating element exceeds the set current, and the bimetallic sheet is heated and bent upwards to break away from the gusset plate so that the normally closed contact is disconnected. Since the normally closed contact is connected to the control circuit of the motor, its disconnection will make the contactor coil connected to it de-energized, so that the main contact of the contactor is disconnected, the main circuit of the motor is de-energized, and the overload protection is realized. After the thermal relay operates, the bimetallic sheet cools down for a period of time and can be reset by pressing the reset button.

Some models of thermal relays also have phase failure protection. The phase failure protection function of the thermal relay is provided by the differential amplifier mechanism composed of inner and outer pushrods. After the thermal relay operates, the bimetallic sheet cools down for a period of time and can be reset by pressing the reset button. Some models of thermal relays also have phase failure protection. The phase failure protection function of the thermal relay is provided by the differential amplifier mechanism composed of inner and outer pushrods. The thermal relay is used for the protection against motor overload, phase failure, circuit unbalanced operation, as well as used for other electrical equipment heating state control.

Thermal Relay Symbol

thermal relay symbol

Types of Thermal Relay

The most commonly used thermal relay types are:

Bi-metal sheet type: The bi-metal sheet is made of two metals with different expansion coefficients, usually manganese-nickel-copper plate, which is rolled to be heated and bent to push the lever and make the contact move.

Thermistor type: A thermal relay made of the characteristic that the resistance value changes with temperature.

Fusible alloy type: When the fusible alloy reaches a certain temperature value by using overload current heating, the alloy melts and the relay operates.

As electrical equipment, there are many types of thermal relays mainly used for motor overload protection, but the most commonly used thermal relays are bimetal thermal relays. The utility model has the advantages of simple structure, small volume, low cost, and good inverse time protection characteristics on the basis of selecting appropriate thermal elements. At present, the thermal relays produced in my country are all bimetallic, which are often combined with contactors to form an electromagnetic starter.

Thermal Relay Working Principle

In the following part, Easybom will give a further introduction to the working principle of thermal relays.

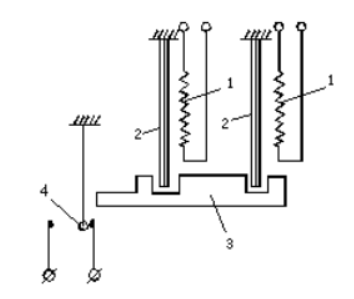

1-thermal component 2-bimetal sheet 3-guide 4-contact

When using a thermal relay to protect the motor from overload, connect the thermal element in series with the stator winding of the motor, connect the normally closed contact of the thermal relay in series with the control circuit of the electromagnetic coil of the AC contactor, and adjust the setting current adjustment knob to make the zigzag lever and the putter are separated by an appropriate distance. When the motor is working normally, the current passing through the heating element is the rated current of the motor. The heating element heats up, and the bimetallic sheet bends after being heated, so that the pushrod just contacts the zigzag lever, but cannot push the herringbone lever. The normally closed contact is in a closed state, the AC contactor keeps pulling in, and the motor runs normally.

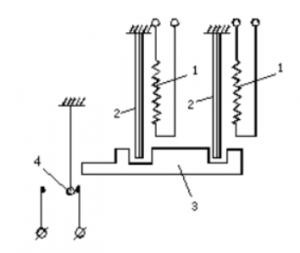

1-Current adjustment cam; 2-Leaf springs (2a, 2b); 3-Manual reset button; 4-Bow reed; 5-Main metal sheet; 6-Outer guide; 7-Inner guide

8-Normally closed static contact; 9-moving contact; 10-lever; 11-Normally open static contact (reset adjusting screw); 12-Compensating bimetal; 13-putter; 14-link; 15-compression spring

The overload protection of thermal relay:

If the motor is overloaded, the current in the winding increases, the current in the thermal relay element increases, the temperature of the bimetal increases, and the degree of bending increases, pushing the herringbone lever, and the herringbone lever pushes the normally closed contact, so that the contact is disconnected and the coil circuit of the AC contactor is disconnected, the contactor is released, the power supply of the motor is cut off, and the motor is stopped and protected.

The functions of other parts of the thermal relay are as follows: the left arm of the zigzag lever is also made of a metal sheet. When the ambient temperature changes, the bimetal in the main circuit will be deformed and bent to a certain extent. At this time, the left arm of the zigzag will also deform and bend in the same direction, so that the distance between the lever and the push rod remains basically unchanged, ensuring the accuracy of the action of the thermal relay. This effect is called temperature compensation.

The screw 8 is an adjustment screw for the reset method of the normally closed contact. When the screw position is to the left after the motor is overloaded, the normally closed contact is disconnected, and after the motor stops, the thermal relay bimetal is cooled and reset. The moving contact of the normally closed contact will automatically reset under the action of the spring. At this time, the thermal relay is in an automatic reset state. When the screw is turned counterclockwise to the right to a certain position, if the motor is overloaded at this time, the normally closed contact of the thermal relay is disconnected. Its moving contact will swing to a new equilibrium position on the right. After the motor is powered off and stopped, the moving contact cannot be reset. The moving contact can be reset only after pressing the reset button. At this time, the thermal relay is in the manual reset state. If the motor overload is faulty, in order to avoid starting the motor easily again, the thermal relay should be reset manually. To adjust the thermal relay from manual reset to automatic reset, just screw the reset adjusting screw clockwise to the proper position

The phase failure protection function of the thermal relay is provided by the differential amplifier mechanism composed of inner and outer pushrods. When the motor works normally, the current through the thermal element of the thermal relay is normal, and both the inner and outer push rods move forward to the proper position. When a phase of the power supply is disconnected and causes a phase loss, the current of this phase is zero, the bimetal of this phase is cooled and reset so that the inner pushrod moves to the right, and the bimetals of the other two phases are bent due to the increase of the current, making the outer push rod move more to the left. Due to the differential amplification, the normally closed contact is pushed to disconnect within a short period of time after the phase failure occurs, so that the AC contactor is released, and the motor is powered off and stopped to be protected.

Differences Between Thermal Relay and Fuse

The thermal relay is used to protect the motor from balanced overload and prevent the motor from overheating and burning. The fuse is only used to protect the circuit. When there are only fuses, it is possible that the breaking current of the fuses on the line is set too large, which is greater than the current that the motor can withstand. At this time, a thermal relay must be used to protect the motor. In addition, there may be a phase failure fault in the three-phase line, or for some reason, only one phase of the fuse is blown. At this time, the motor needs to choose a thermal relay with phase failure protection according to the connection method of the motor stator. (Generally, the thermal relay is only installed with two phases, and the corner connection must have phase failure protection)

- Both fuses and thermal relays have inverse-time action curves, and their active principles are inverse-time action based on the heat capacity of the loop current;

- Due to its large thermal capacity, the fuse has a large error in its action at low current, so it is often used as a short-circuit current element in the circuit breaker. The thermal relay has a small thermal capacity, so when the current is large, its action error is large, so it is often used as a protection for operating components (such as contractors, etc.)

- The fuse itself has a great arc-breaking capacity, so it can be used as a component in the primary circuit. The thermal relay has no arc braking ability, and the current of its contacts is very small, so it can only be used as a secondary element. After using its contacts to connect the primary element, there is a primary element to open the circuit.

- Except for the return-type fuse, which can be used multiple times, most fuses can only be used once. Once they operate, they should be replaced. If the current reaches its softening current value, it should also be replaced to avoid future malfunction.

What is the difference between thermal relay and fuse?

The function of the thermal relay is overload protection.

The function of the fuse is overload and short circuit protection.

Because it takes several seconds for the metal sheet in the thermal relay to heat up, and the short circuit is instantaneous, the thermal relay cannot be short-circuit protected.