Flow measurement is critical as it determines the profit or loss of a company. The flow measuring device is used to measure the flow rate or Flow Rate (Volumetric or Mass) or the amount of fluid passing through a pipe.

The flowmeter uses many different applications to measure the volumetric flow rate or mass flow rate. The application determines the type & capacity of the flowmeter. Fluids, gases and liquids are measured by the volumetric flow rate or mass flow rate. Both are related to the material density with the volume flow rate referred to in Q and mass Flow Rate as ṁ in the equation:

Mass flow rate = Volumetric flow rate × Density

ṁ = Q x ρ

There are many types of flowmeters and vary according to the application, fluid and composition, including materials manufacturing device. So let’s dive in;

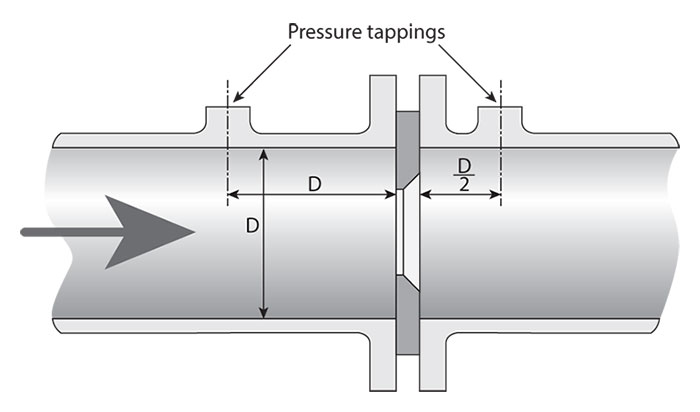

Differential Pressure Flow Meters

Pressure measuring devices Flow teams measure the differential pressure on both sides of the hole or nozzle Orifice where proportional to flow directly proportional to the square root of the pressure difference output. The device contains the initial elements of the Primary Elements and another secondary. The task of the initial element Primary Element is the formation of differential pressure on both sides may be a nozzle Flow Nozzle or Petc tube Pitot Tube or perforated disc Orifice Plate or device Venechura the Venturi. While the Secondary Element task is to measure this pressure difference and convert it to a Signal.

Pressure gauges for flow measurement (5-1) represent flow meters used worldwide. It is usually used in the oil and gas industry, together with central air conditioning units, beverage factories, water plants, pharmaceutical factories, metallurgy and paper industry as well as in chemical applications.

Differential Pressure Flow meters are meant to measure the differential pressure across an orifice where the flow is related to the square-root of differential pressure produced. There are also primary & secondary elements in differential flow meters. The primary element produces a change in kinetic energy while using flow nozzle, orifice plate, pitot tube, or venturi flow meters. The secondary element measures the differential pressure that further provides the signal.

Differential pressure meters are supposed to represent around 1/5 of all flow meters around the world. They’re commonly used in the oil & gas industry, along with HVAC, mining, beverage, pharma, water, paper and many other chemical applications.

Velocity Flow Meters

Speed measuring devices – the Velocity Flow Meters – measures flow velocity and flow of which is calculated volumetric rate Volumetric Flow Rate. The sensitivity of these devices is lower when Reynolds Number of liquid is above 10,000 of speed measuring devices turbine.

Velocity meters measure the velocity of the stream to calculate the volumetric flow rate. These flowmeters are less sensitive when the Reynolds number of fluid shoots above 10K. Velocity flow meters include turbine, vortex shedding, paddlewheel, electromagnetic and sonic/ultrasonic meters.

Mass Flow Meter

Mass Flow Meters are more efficient in Mass production processes, which measure the force resulting from mass acceleration. More specifically, force is measured when the mass moves per unit of time rather than measuring the volume per unit of time. Coriolis Mass Meters and Thermal Dispersion Meters are flow meters.

Typical applications of biomass flow devices are related to chemical processes. Besides the chemical & gas industries, the typical industries that use this type are the pharmaceutical industry, the energy field, mining and sewage plants.

When it comes to mass related processes, the mass flow meters are more effective as they measure force resulting from the acceleration of the mass. Precisely, this force is measured as the mass/unit, instead of the volume/unit. Mass flow meters include Coriolis mass meters & thermal dispersion meters.

Typical applications for mass flow meters are almost related to the chemical processes. Besides the chemical & gas industries, traditional industries using mass meters include power, pharma, mining & wastewater.