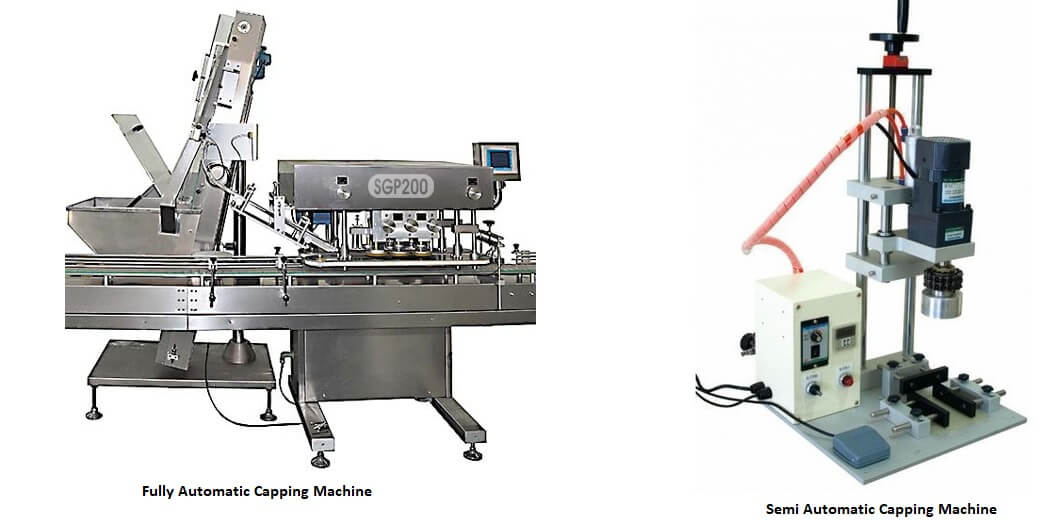

Currently, an automatic capping machine can be available in a selection of forms. They are normally based upon the sort of cap that’s being employed as well as the level of automation needed. If production demands reach a certain amount or degree, an auto capper ends up being a full requirement, but even for low or average production facilities, these machines use more benefits.

Bottle Gripping Pressure

Top Load

Similar to the cap and container gripping sensitivity, the top load sensitivity of the release torque measurement mainly depends on the details package layout. The optimal top lots needs to be assessed as well as optimised for each item separately. Particular installations need minimised top load during the turning of the lid, for instance, when examining the string breach, seal breach and also bridge break twist of a fastener with a tamper evident band. Minimised top load is likewise helpful when determining the breeze torque of the tamper obvious band throughout a cap securing pattern or when determining torque on a loosened cap.

Induction Sealing

Because of the induction heating of the steel foil inside the cap, the container and also cap might malform, grow after that diminish. Because the cap and also the container are normally made of various plastics, the timing as well as the prices of expansion/shrinking are different, because of this the twist between the threads can change considerably in the past and also after the induction sealing process.

Benefits of automatic capping

Security, Integrity, and Uniformity

By computerizing the capping process, one of the major benefits is the repeatable activity given by the capping machine. As each of the caps as well as containers are fastened in the same way, the automation used by the product packaging devices provides protected, trustworthy, and also consistent sealing. Manual capping and even semi-automatic capping require manual work, which then generates problems such as fatigue, which can result in irregular sealing, along with defect product. An on a regular basis and effectively maintained automatic capping device can deal with these problems.

Enhanced Rate

Automated cappers likewise increase the complete quantity of vessels or phials that are secured during the course of the manufacturing day. If you were to hand cap, or operate a semi-automatic container capper, the process takes even more time as well as needs the controller to hand-place a cap on the canister prior to fastening it. With mechanical equipment, the cap distribution structure is managed, which leaves an operator to just discard the bulk caps into the close-by hopper once in a while.

As you can witness, the advantages used by a mechanical capping device are substantial and can improve your time and also rates considerably. If you have actually been uncertain about this purchase, the info right here makes it transparent that this is a clever investment.