There is no doubt that all industries strive for the perfect way to produce, right from the moving assembly line to machines taking overall operations. Each manufacturer is looking to cut down on error and double down on supply while taking the shortest time possible. While a trained person can check one of the two boxes, it is essentially impossible for a human to have zero error. This is where machines come in.

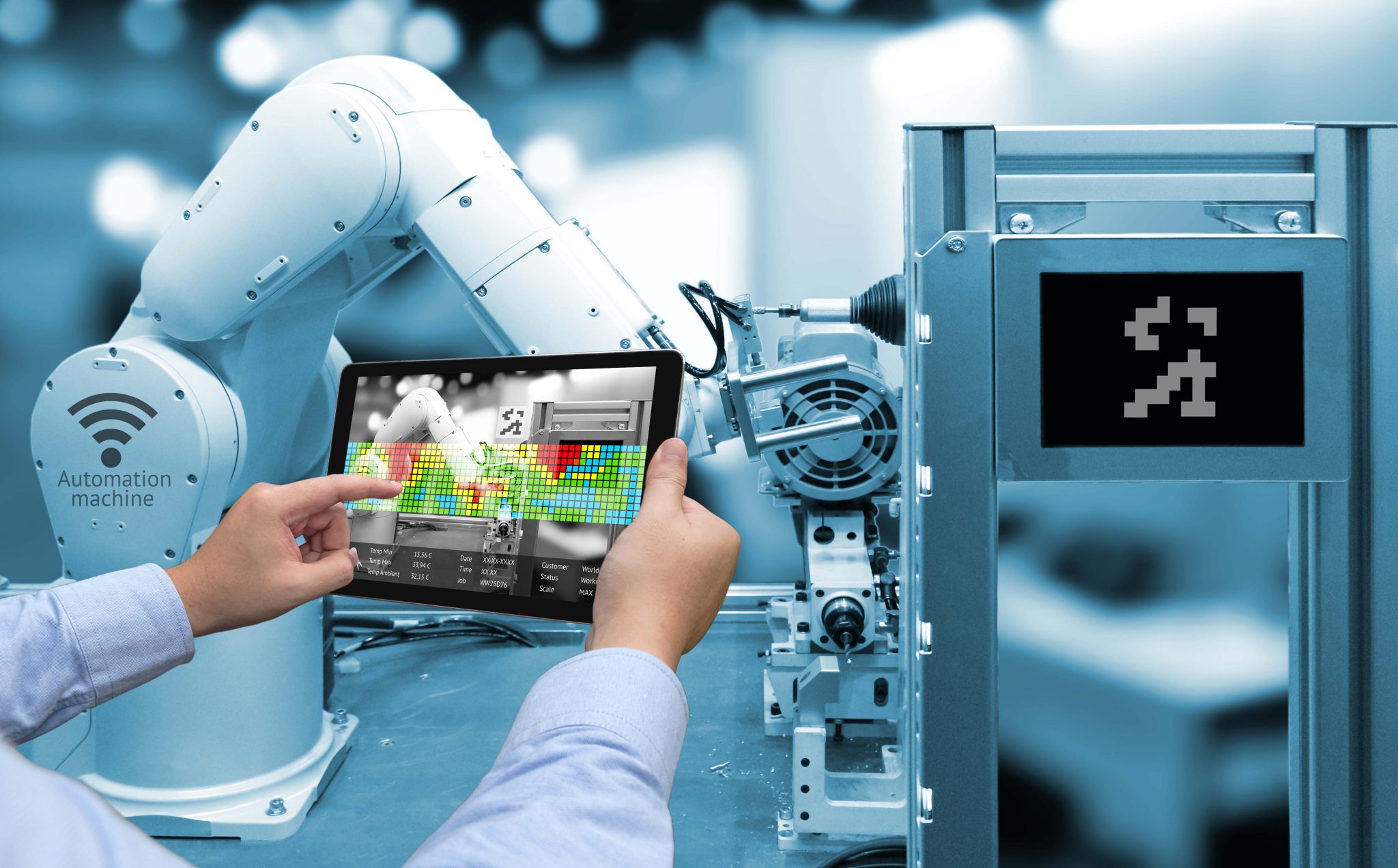

An industrial automation system is a connected network of systems that control a single or set of processes or machines that perform repetitive tasks. They operate on their own and are aimed at cutting down on the effort of people who are doing tasks that require little or no decision making are merely repeated. Through programming, the machines can be set to perform mechanical functions during the manufacturing process.

By putting standardized tasks under the purview of a machine, you are able to free up human resources for other tasks that would require more thinking on their feet. This has been made possible only with the advent of the Internet of Things and the upcoming 5G boom. The faster network will change how we operate with all devices connected to each other, ushering in speed to industrial automation that has never been seen before.

Here are five benefits of industrial automation that ensures any manufacturer stays ahead of the curve.

- More Output, Less Error

No matter how competent your staff is, they are still limited by their speed and are prone to error, no matter how small. Industrial automation cuts down on that error but also ensures that there is no compromise on the speed or duration of production. This combination makes it a winner for industries that are striving to cater to the explosion of demand.

The error-free automation methods use specialized industries like automobiles and heavy machinery that have various heavy-duty standardized tasks. This is also because automation is able to maintain a greater level of consistency across products in terms of quality.

- Easy To Add More Tasks

If you want to expand your assembly line, you will need to invest in the staff’s training so that they can execute the tasks efficiently and safely. The chances are that there will still be some room for error in the first few weeks after training.

Now consider industrial automation, which can feed the new set of instructions into the system at a fraction of time. The system will work perfectly on the first day and will ensure no break in the process.

This is particularly useful when the new task or machinery is complicated and can lead to production delays. In this way, automation also allows you to maintain quality, even as you add more functions to the process.

- Automation Is Safer

Production lines can be prone to injuries as machines break down or due to a fault in the system. This can happen despite all the precautions by the manufacturer. Industrial automation is able to bypass this completely and provide a safer environment for the workers.

- Spend More To Save More Later

While there is a high cost to shift to industrial automation, the price tag is more than worth the benefits in the long run. One of the benefits of automation is the data that it records that can prove useful for further improvements in the system and, more importantly, to identify your line’s errors. This will allow you to identify any possibility of machine failures before it is able to disrupt the process.

Similarly, the investment will pay off as you can scale quickly with no massive investment in the new workforce. This function lets you reduce any breaks in the service to a minimum as the new task can be added in a short period of time.

- Better Use Of The Manpower

By delegating repetitive tasks to machines, industrial automation allows you to free up your workers’ time to take up more value-added tasks. They are able to focus on activities that require decision making and thinking on their feet. It also leads to better working conditions for them as they work fewer hours and are not bound by some output related target on the production line. This way, they provide greater benefits to the company.

Industrial automation is the way to go as demand outstrips the supply and is the only way for a manufacturer to maintain an edge over competitions. However, it is advisable that you get in touch with a trained professional who can help you find your manufacturing process’s best fit. Alternatively, you could also approach leading electrical providers and discuss your requirements with them to get personalized solutions!