The Printed Circuit Board Assembly has progressed through the years rapidly and is an integral part of the various assortments of equipment. The printed circuit board uses a straightforward technique and has a circuit board. Whatever it is, when people talk about PCBs, it’s about the components involved at the beginning of the circuit.

They include graceful strength and other components. In the PCB world, printed circuit boards value a ton of flexibility. Small changes in consumer standards, alongside modern development improvements, can see dramatic changes in PCB marketing.

Develop understanding

You may want to know how PCB works with the supply of many modern electronics. Without someone else, the PCB cannot do anything. Only when the PCB is attached to certain parts of the system; it can carry electrical charges to the entire frame. It is a strong concept of the board, which borrows support for the entire structure. PCB Assemble Houses is a way to establish connections with electrical components through wired circuit boards.

Lots to use

Just like anything else, PCBs are affected to a great extent by climate, social, and political factors. The manufacturing process must be in line with current mechanic standards. In traditional cases, PCBs used fiberglass as a substrate, which is an eco-friendly material. With the rapid development of mechanics, PCB products can begin to use other types of products.

Fiberglass can replace gum coated copper and liquid crystalline polymers. These advanced features are essential for speeding up the process. The Printed Circuit Board Assembly serves businesses, for example, stationery, instruments, consumer gadgets, and smart devices.

From a dress standpoint

Crops related to PCB production today are no longer dependent on traditional development. Again, they rely on knowledge-driven skills. In all manufacturing factories, the smartest manufacturing system is being treated. This design includes monitoring of occupancy, improvement of product design, and reduction of lead time. Consumer gadget has been using PCB innovation in the last few decades. Similarly, as smartphones that use printed circuit boards, wearable changes are also required. With stopping techniques, the efficiency of the solutions can create alarming shapes.

The world of medicine

Throughout human history, the development of digital has revolutionized the world of medicine. These include keeping patient records safe at the annual level, getting relief from medical activities through use and phones.

Technological advances have affected PCBs in a number of ways. Part of the board cameras are small enough that they can stabilize. The smaller than normal size also causes these cameras to be installed effectively within the human body.

Doing in the right way

You need to be careful about the process when choosing a PCB provider. You should choose a Kingford company that is known to have a strong reputation in the market.

It is best to use the Printed Circuit Board Assembly.

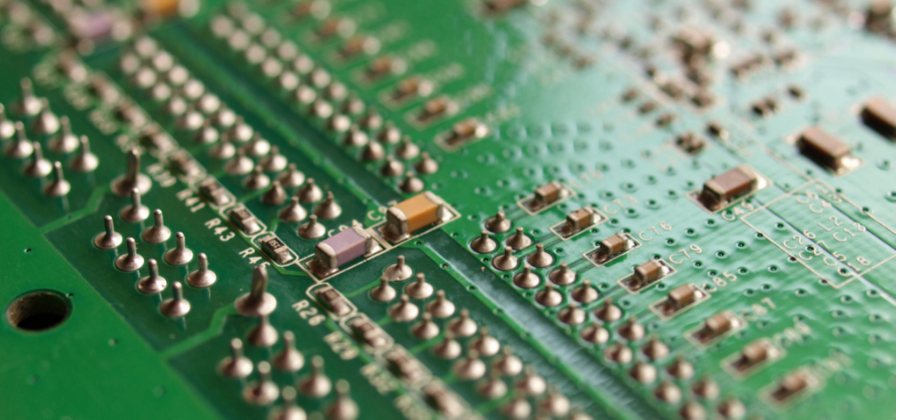

The vast majority of people do not have a clear idea of what the Printed Circuit Board Assembly means and how they are brought in. A lot of people are confused about District boards, especially when there is a chance that they are not properly displayed. PCB’s are often used to support and connect electrical equipment to a pan. Description of front parts of PCB’s capacitors and resistors.

They are displayed on various electrical components that are connected by conductive courses, paths, or recordings made on the material of bird caregivers that are stored in a non-conductive substrate. If it has both practical and non-practical courses, it has come to be known as the Printed making panel (PWB). If a group has a cable and other computer components, the PCB is currently known as a printed routine suspended or here, and then known as PCB Assembly Houses.

PCB assembly Simple houses, however, are still under construction. The lower price went up again because of their efforts. This is because the experiment of form requires some time and so on. However, PCN has not failed and quickly in terms of PCB manufacturing.

Almost complete business with PCB design, the QC, and design requirements are handled by the Company Linking Electronic gadgets segments (IPC) organization. In the case of PCB manufacturing, usually the printed circuit is constructed by a joint part of the bird feeder on the substrate, or now and again with two edges, which makes it free of PCB. After this, an incomplete bird observer is placed in isolation if a short-term secrecy has become significant with the record, and the average bird observer we need on PCB will remain.

Anyway, here it is, and there depends on the size of the PCB mode or the cost of progress. There is a process also called light electroplating, which is a complex process consisting of records or a thin layer of bird that attaches a portion of the substrate to the lower surface.