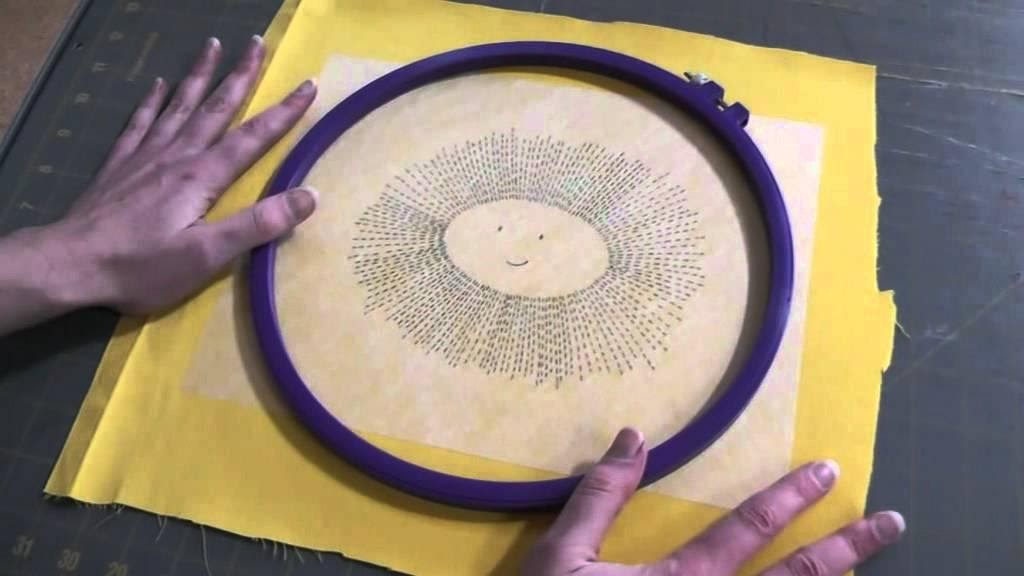

Machine Embroidery is straightforward and fun – apart from the stabilizing part, the incorrect choice can ruin your work.

The utilization of backing lessens the stress of the embroidery on the material.

Without a backing, these fabrics will disappear into the opening in your home appliance, and be ruined forever.

Embroidery stabilizers do tons of excellent, actually, when chosen right. For one, it gives the material the strength and skill to touch the load of the embroidery work and such. It gives the needed stiffness that’s not there in unstable thin fabrics or slippery fabrics like chiffon and silks.

If you’re using thick heavyweight fabrics, you always don’t need backing but just in case of most other fabric it’s better to use some quiet backing when doing machine embroidery, and even for a few intense hand embroidery. They’re also used when making quilts, sewing collars, pockets, hems etc.

Why Use Stabilizers

The 3 main considerations in choosing stabilizers are the type of cloth you’re using (its structure and stability), the effect you would like, and the stitch density. Other factors like colour, stitch length, stitch speed, size of the embroidery and stability of the planning are all important.

Test the stabilizer on your fabric and, therefore the sort of stitching together with your home appliance first before you employ it on your real work. This way, you’ll know whether the backing is sufficient for your chosen fabric, particular stitching, home appliance tension etc. or worse, will damage the material.

Buy the acceptable non-shrinkable non-stretchable stabilizer. Get a dense stabilizer for dense fabrics (Thickness isn’t equivalent to denseness in these materials).

Sew in tear-off stabilizer

Tear away (sew-in) may be a stabilizer that will be torn away completely or partially after the work is completed. It’s a favourite to be used with woven fabrics and fabrics that don’t stretch – it’s easy to use.

Sew in stabilizers aren’t fused to the material – they’re kept under the material and temporarily fused to fabric with adhesive spray and it’s available in many weights.

But it’s not much fitted to thin unstable fabrics or ones that stretch or ones with open/loose weave. Lightweight, medium weight and heavy-weights are used counting on the material you’re using. Some ultra-firm stabilizers can even make the material stand stiff.

Paper

The paper is employed as a convenient backing that helps the material to manoeuvre smoothly on materials that have trouble moving.

But not as effective because of the ones you purchase. You can’t hoop paper.

Fusible Stabilizer

This is the type of backing that’s fused to the rear of the material using heat. These stabilizers are available in different fabric weights and an appropriate one should be chosen for the proper effect.

Some will have two side adhesive – you’ll use it to fuse fabric together – it is beneficial in applique work and for stitching hems. It’s also useful when repairing holes in the fabric.

And an identical weight between stabilizer and fabric is important, otherwise, there’s an opportunity for bubbling. A sheer weight fusible is employed on delicate fabric to offer good stability to the skinny fabric once you sew or do embroidery. For heavyweight fabric, an identical stabilizer is employed.

Sticky-backed Stabilizers

A sticky-backed stabilizer is hooped then the paper backing is removed then the material is kept thereon, for embroidery.

This stabilizer features a paper cover on its adhesive side. This stabilizer might be cut away, torn off or washed away. this is often primarily used once you cannot hoop the material – it might be a little one or simply can’t be hooped sort of a shirt collar or will leave marks if hooped like.

Dimensional backing

Fleece or a commercially available puff backing is employed once you need a backing that can give some padding, an honest dimension, even bulk. Fleece is typically utilized in quilting, and for creating handbags. Fleece is out there in several weights and also as sew-in and fusible.

Sew in Cutaway stabilizers

After the work is completed you’ll cut it faraway from the rear leaving a little allowance all around the design.

It is also preferred over tear-off where you would like continued protection even after the embroidery is completed.

A medium-weight cutaway is the most popularly used one for many others.

For Fleece, you’ll have to use a cutaway stabilizer and a topping stabilizer.

Conclusion

These are some of the best stabilizers that you can use as a backing for cloth in embroidery and sewing. Please note that you are not limited to these stabilizers only. It all depends on your project requirements and needs. If you need any advice or help about the topic or anything related to embroidery digitizing, feel free to reach out to us at Migdigitizing.

Thanks For Reading

More Read On Mynewsfit