Introduction:

Aluminium coping, also known as aluminium cap flashing, is a key component in the construction industry, providing protection and aesthetic appeal to various architectural structures. Its versatility, durability, and sleek appearance have made it a popular choice among designers, architects, and builders alike. In this article, we will delve into the features and benefits of aluminium coping, exploring its applications and highlighting its significance in modern construction projects.

Definition and Function:

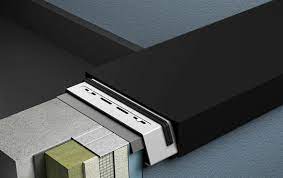

Aluminium coping refers to a protective covering placed on the top edge of parapet walls, low-rise roofs, and other horizontal surfaces of buildings. Its primary purpose is to prevent water infiltration, providing a watertight seal between the structure and its surrounding environment. It serves as a barrier against moisture, wind, and other external elements, effectively safeguarding the building envelope.

Versatility:

One of the standout characteristics of aluminium coping is its versatility. It can be customized to suit various architectural designs and structural requirements. Aluminium coping systems come in a range of profiles, sizes, and finishes, allowing architects and designers the freedom to select the most appropriate option for their projects. The flexibility of aluminium coping makes it suitable for both construction and renovation projects, regardless of the building’s style or purpose.

Durability and Longevity:

Aluminium coping is renowned for its exceptional durability and longevity. It is resistant to corrosion, ensuring that it remains functional and visually appealing for an extended period. The material’s inherent strength makes it capable of withstanding harsh weather, including heavy rain, extreme temperatures, and UV exposure. Unlike other coping materials, such as wood or PVC, aluminium coping does not rot, warp, or fade over time, reducing maintenance requirements and costs.

Easy Installation and Maintenance:

Another advantage of aluminium coping is its ease of installation. It can be prefabricated and cut to size, simplifying the installation process for contractors. Aluminium coping systems often feature a snap-on design, allowing for quick and secure installation without the need for complex tools or techniques. Additionally, its low maintenance requirements make it a cost-effective solution. Routine cleaning and occasional inspections are usually sufficient to maintain its functionality and aesthetics.

Aesthetics and Customization:

In addition to its functional benefits, aluminium coping adds an aesthetic touch to architectural structures. Its sleek and modern appearance enhances the visual appeal of buildings, contributing to their overall design. Aluminium coping can be powder-coated or anodized in a wide array of colors, providing endless possibilities for customization. This feature allows architects to achieve a seamless integration of coping with the building’s exterior, complementing the overall architectural style.

Sustainable and Environmentally Friendly:

Aluminium is an environmentally friendly material with excellent recyclability. It is estimated that around 75% of all aluminium produced is still in use today, making it one of the most recycled materials in the world. Choosing aluminium coping contributes to sustainable construction practices, reducing the environmental impact of building projects.

Aluminium coping serves as a vital element in modern construction, providing both functional and aesthetic benefits. Its versatility, durability, ease of installation, and low maintenance requirements make it an ideal choice for architects and builders. With its ability to protect structures from the elements while adding a touch of sophistication, aluminium coping continues to be a preferred option in the realm of architectural design. As the construction industry evolves, aluminium coping will undoubtedly remain an essential component in creating excellent and visually stunning buildings.