Welcome to the world of factory automation! In today’s technologically advanced society, the concept of automating manufacturing processes is prevalent. Explore what is factory automation, the evolution, technologies, challenges, and components of factory automation for a deeper understanding. Get ready for an exciting journey through the wonders of modern industrialization! So, grab your preferred beverage, sit back, and prepare to be amazed!

Definition of Factory Automation

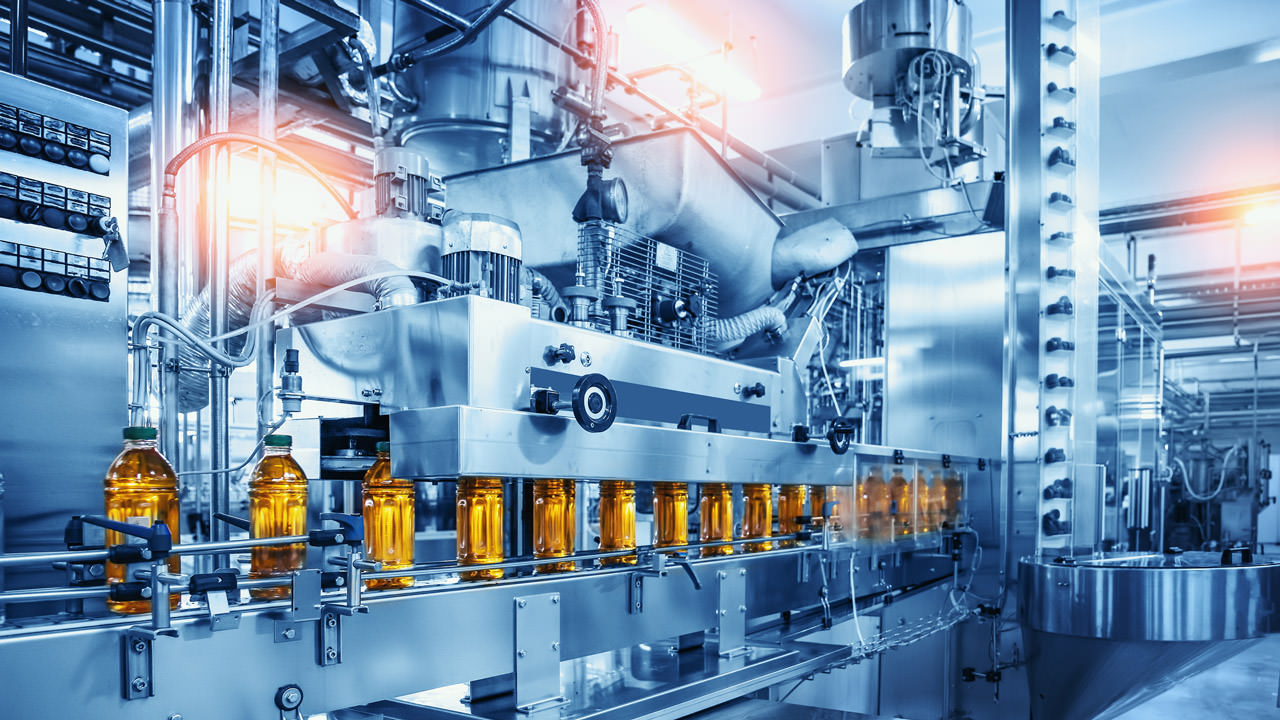

Factory automation transforms manufacturing by replacing manual labor with intelligent machinery, enhancing productivity and efficiency. This versatile approach spans industries, from automotive to pharmaceuticals, with possibilities ranging from small-scale robotic arms to large-scale AI-controlled systems. The use of sensors and real-time data monitoring, analyzed by sophisticated software, is central to this transformation.

It facilitates informed decision-making based on predefined rules or machine learning algorithms. In conclusion, factory automation revolutionizes traditional manufacturing, utilizing cutting-edge technologies to boost efficiency and productivity while minimizing human error. Ongoing advancements in robotics and AI promise even greater innovations, paving the way for an increasingly automated future in industrial production.

History and Evolution of Factory Automation

The history of factory automation traces back to the early 20th century, marked by the introduction of assembly line production pioneered by Henry Ford. This innovation revolutionized manufacturing, enhancing efficiency and streamlining processes. Technological advancements, especially in the 1950s and 1960s, brought computers into factory operations, providing better control and increased productivity.

Subsequently, robotics became a cornerstone of automation, with industrial robots reducing human labor through precise and speedy task execution. Integration of sensors and AI further elevated their capabilities. The digital age ushered in Industry 4.0 or Smart Manufacturing, leveraging IoT and cloud computing for interconnected systems. This facilitates real-time monitoring and analysis across production stages, optimizing decision-making.

The evolution continues with innovations like collaborative robots (cobots), machine learning for predictive maintenance, and autonomous vehicles within factories. These advancements target improved efficiency, quality control, flexibility, and competitiveness in modern manufacturing. From assembly lines to today’s integrated systems powered by cutting-edge technologies, factory automation has come a long way, shaping the landscape of modern manufacturing.

Benefits of Factory Automation

The key benefits of factory automation. Here’s a refined version:

- Increased Efficiency: Factory automation enhances productivity by reducing human error, allowing machines to work faster and more precisely, ultimately increasing output levels.

- Cost Reduction: Implementing automation optimizes resources, minimizes waste, and streamlines production processes, resulting in lower operational costs, reduced labor expenses, and decreased material wastage.

- Improved Quality Control: Automated systems ensure consistent and accurate task performance, eliminating variations caused by human error or fatigue, and leading to standardized outputs that meet high-quality standards.

- Enhanced Safety: Factory automation reduces the risk of accidents or injuries associated with manual labor-intensive tasks, as machines handle dangerous or repetitive jobs.

- Flexibility and Scalability: Automated systems easily adapt to changing production demands, allowing for quick reconfiguration or customization without significant disruptions or investments.

- Data Collection and Analysis: Automation enables real-time data collection and analysis, providing insights into bottlenecks, inefficiencies, and areas for improvement within the manufacturing process.

- Competitive Advantage: Implementing factory automation provides a competitive edge in the fast-paced market environment, where speed, efficiency, quality control, and cost-effectiveness are important factors for success.

By strategically embracing factory automation technologies tailored to their needs, businesses position themselves to not only improve operational efficiencies but also transform their overall manufacturing capabilities, gaining a competitive advantage in the market.

Common Technologies Used in Factory Automation

In the realm of advanced manufacturing, factory automation stands as a cornerstone for improving productivity and efficiency. Notable technologies driving automation include:

- Robotics: Integral to modern factories, robots handle tasks once done manually, offering precision and speed in executing repetitive or hazardous operations.

- Programmable Logic Controllers (PLCs): These computerized control systems monitor and manage various processes within the factory, responding to specific inputs for smooth machinery and equipment operation.

- Sensor Technology: Sensors detect changes in physical conditions like temperature, pressure, or proximity, providing real-time data for automatic adjustments and preventive measures, and optimizing performance.

- Machine Vision Systems: Using cameras and image processing algorithms, these systems inspect products for defects or ensure accurate assembly, swiftly identifying deviations from quality standards and improving production outcomes.

- Communication Networks: Ethernet-based protocols facilitate connectivity, enabling seamless integration and coordination among automated system components. This ensures efficient data exchange and synchronized operations.

These technologies collectively contribute to achieving higher levels of productivity, accuracy, safety, cost-effectiveness, and overall operational excellence within automated factories.

Challenges and Limitations of Factory Automation

While factory automation brings numerous benefits, several challenges and limitations must be considered:

- Initial Cost: The significant upfront investment, particularly for small and medium-sized enterprises, can be a barrier. However, long-term savings in increased productivity and reduced labor costs often offset this initial expense.

- Integration Complexity: Integrating different automation technologies into existing processes requires careful planning to ensure seamless integration without disrupting production flow. Employee training for operating and maintaining automated systems is also a time-consuming challenge.

- Maintenance: Automated machines, while designed for efficiency, require regular maintenance and repairs. Poorly managed maintenance can lead to downtime, impacting productivity.

- Adaptability: Adapting automated systems to handle varying product specifications or changes in demand is a challenge. Flexibility is important in a market where customization plays a significant role.

- Cybersecurity Concerns: Interconnected devices and networks increase the risk of cybersecurity threats, including data breaches or unauthorized access, posing potential disruptions or compromise of sensitive information.

In conclusion, despite these challenges, ongoing technological advancements address these issues as manufacturers aim for more efficient production processes. Understanding these potential obstacles enables businesses to better prepare for success in an increasingly automated future.

Types of Automation Systems Used in Factories

In the realm of factory automation, various systems play an important role in streamlining operations and enhancing efficiency. Here are some common automation technologies:

- Robotics: Robots excel in performing precise and speedy repetitive tasks, reducing human error and significantly increasing productivity.

- Programmable Logic Controllers (PLCs): Computer-based controllers automate machinery and equipment on the factory floor, making decisions based on pre-programmed instructions derived from sensor inputs.

- Conveyor Systems: These systems facilitate the seamless movement of materials or products within the factory, allowing for efficient transportation without manual intervention.

- Industrial Internet of Things (IIoT): Interconnected devices with embedded sensors collect data for insights into machine performance, maintenance needs, and overall operational optimization.

- Automated Guided Vehicles (AGVs): Self-driving vehicles navigate the factory floor, transporting materials or products safely using lasers or magnets without human assistance.

- Computer Numerical Control (CNC) Machines: Controlled by computer programs, CNC machines precisely manage cutting tools’ movements in manufacturing processes, ensuring repeatable and accurate production.

In conclusion, While these examples represent common automation systems in use today, ongoing advancements continue to drive rapid innovation in the field of factory automation.

Components of a Typical Automated Factory

In a well-optimized automated factory, several key components collaborate seamlessly to enhance productivity and efficiency:

- Control System: Serving as the brain of the operation, the control system oversees and coordinates all activities within the factory, ensuring the harmonious operation of each component.

- Robotic System: Highly advanced robots perform intricate tasks with precision and speed, taking over repetitive or hazardous jobs, contributing to increased output, and operating continuously without fatigue.

- Network Infrastructure: Facilitating communication among different factory components, the network infrastructure enables real-time data exchange and coordination, ensuring smooth operations throughout the production process.

- Sensors: Vital for providing information on equipment performance, environmental conditions, and product quality, sensors enable proactive maintenance and help prevent costly breakdowns by continuously monitoring key parameters.

- Automated Guided Vehicles (AGVs): AGVs efficiently handle material handling tasks, navigating predefined paths using advanced guidance systems, such as laser scanners or magnetic tape markers, to transport materials without human intervention.

- Manufacturing Execution Systems (MES): Software programs like MES manage production schedules, track real-time inventory levels, monitor machine utilization rates, and provide essential analytics on overall manufacturing performance.

These components work in harmony to create a seamlessly automated environment where processes flow smoothly, maximizing productivity in the automated factory.

Conclusion

In conclusion, factory automation has undergone a transformative journey from the Industrial Revolution to today’s era of robotics and machine learning, enhancing accuracy and precision in tasks. The substantial benefits include faster production, improved quality, and significant cost savings, driven by key technologies like robotic arms, conveyor belts, PLCs, sensors, CNC machines, AI, IoT devices, and data analytics. Challenges persist, notably high initial costs and a skills gap, especially for small businesses.

Different automation types address diverse production needs, from fixed to programmable and flexible systems. A typical automated factory seamlessly integrates various technologies, highlighting automation’s comprehensive impact on modern manufacturing. Navigating challenges, the ongoing integration of advanced technologies promises continued improvements in efficiency and competitiveness for the future of industrial production.