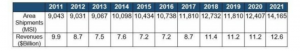

As the upstream material of semiconductors in the world, the production capacity of silicon wafers is one of the important factors restricting the supply and demand of semiconductors in the world. Driven by demand, the global silicon wafer is in a stage of rapid growth. According to data released by SEMI, global shipments of silicon wafers increased by 14% year-on-year in 2021, with total shipments reaching 14.165 billion square inches (MSI), revenue up 13% year-on-year to $12.62 billion.

On the price side, due to the shortage of supply and demand, the price of wafers around the world is also rising. Siltronic (Siltronic) says the price of wafers in 2021 is 10% higher than the previous year, while another wafer giant, Shenggao (Sumco), expects the price increase to continue until at least 2024.

Photo Source: SEMI

The tide of production expansion under exuberant demand

According to data released by WSTS at the end of last year, the global semiconductor market grew by 25.6% to US $553 billion in 2021, the largest increase in a decade, and is expected to continue to grow by 9% in 2022, and the market will hit record highs one after another. As the engine of the semiconductor industry, the world’s major wafer factories have expanded production in the past year, thus driving the demand for equipment and materials.

In terms of revenue, Taiwan’s global wafers reached NT $61.13 billion (about 13.644 billion yuan) in 2021, an increase of 10% year-on-year and an all-time high. Global wafer had been interested in acquiring Germany’s Siltronic to increase market share and enhance its wafer manufacturing capacity, but the acquisition was vetoed by the German government. After the failed acquisition, Global Wafer began to expand its capacity by building factories, announcing that it would invest 100 billion New Taiwan dollars (about 22.32 billion yuan) to expand its existing capacity in 2022-2024.

Siltronic’s revenue in 2021 was 1.405 billion euros (9.825 billion yuan), up 16%. It has a new 12-inch factory in Singapore, and its financial report expects prices to rise further in 2022.

Japanese factory Sumco recently said that the orders it has received cover all of the company’s 12-inch wafer production capacity over the next five years. As for 6-inch and 8-inch wafers, the company does not accept such long-term orders, but demand is likely to continue to outstrip supply in the coming years. Although customers have an urgent need for long-term supply, Sumco can no longer expand production this year.

On the price side, Sumco says the price of 12-inch and 8-inch wafers will rise by an average of 10% this year. It is estimated that Sumco will raise prices periodically before the new capacity is put into operation in 2024. In addition, Sumco also announced that it will spend 228.7 billion yen (13.27 billion yuan) to build a new plant and expand 12-inch silicon wafers, its first investment in a new plant since 2008, but it will take at least a year and a half to release new capacity.

In addition, Taiwan’s Taisheng’s combined revenue last year was 12.166 billion New Taiwan dollars (about 2.715 billion yuan), the third highest in history. As the price increase effect ferments, the company’s overall performance is expected to grow by more than 30 percent this year. Do not rule out the opportunity to surpass the 2018 NT $16.358 billion (about 3.651 billion yuan), a record high.

Hejing Technology reported that its consolidated revenue in 2021 was 10.317 billion New Taiwan dollars (about 2.303 billion yuan), an annual increase of 39.3%, the second highest in history. Hejing is expected to grow by more than 30 per cent this year, at least setting another record and surpassing the high of NT $14.795 billion (about 3.302 billion yuan) set in 2010.

At present, the major wafer manufacturers around the world have started production expansion plans, but it will take a year and a half to release capacity as soon as possible, so semiconductor wafers will still be in short supply in the short term.

The performance of local silicon wafer manufacturers

On the mainland, the Shanghai silicon industry announced its results earlier this month, KuaiBao, whose revenue in 2021 was 2.467 billion yuan, an increase of 36.19 per cent and a net profit of 145 million, an increase of 66.58 per cent.

According to relevant data, by the end of the first half of last year, Shanghai Silicon’s Shanghai Xinsheng 300mm semiconductor wafer production capacity has reached 250000 wafers / month, and by the end of 2021 it has reached the production target of 300000 wafers / month; the combined production capacity of its subsidiary Xinao Technology and Okmetic200mm and the polished wafers and epitaxial wafers has exceeded 400000 wafers / month; the combined production capacity of its subsidiary Xinao Technology and Okmetic200mm and the following SOI wafers has exceeded 50, 000 wafers / month.

At present, customers, including Changjiang Storage and Wuhan Xinxin, have signed long-term supply agreements with Shanghai Xinsheng, which is owned by Shanghai Silicon, from 2022 to 2024. Among them, the expected transaction value from January to June in 2022 is 155 million yuan and 80 million yuan respectively, while the transaction value of the above-mentioned companies from January to November 2021 is 143 million yuan and 103 million yuan respectively.

In addition, recently, the Shanghai silicon industry disclosed the results of the fixed increase, which issued a total of 5 billion yuan of shares to 18 specific targets, and the second phase of the big fund subscribed 1.5 billion yuan, accounting for 30% of the total. This increase in the Shanghai silicon industry is mainly used for the R & D and advanced manufacturing projects of 12-inch high-end silicon wafers.

In addition to the Shanghai silicon industry, in January this year, the full automatic production line of Guojing (Jiaxing) semiconductors was also opened. The production line is planned to produce 4.8 million 12-inch silicon wafers per year, and its products are currently in the stage of delivery to customers for testing and certification.

Guojing’s main business is to develop, produce and sell 12-inch electronic-grade single crystal silicon wafers and polished wafers and epitaxial wafers that meet the chip process standards of less than 28 nanometers.

Summary

As an important part of the semiconductor industry chain, silicon wafer is the cornerstone of semiconductor manufacturing. Although major silicon wafer enterprises are accelerating production expansion, it will take at least a year and a half from construction to commissioning, which also means that in the short term, the demand for silicon wafer still tends to be strong, and silicon wafer enterprises will also achieve good results.

On the other hand, benefiting from this wave of capacity shortage, local silicon wafers have also obtained more growth opportunities, whether it is the substantial increase in revenue and net profit of the silicon industry in Shanghai, or the opening of Guojing’s fully automatic production line, it is proof of the continuous progress of local silicon wafers.

For more information please visit easybom