Thermistor Definition

A thermistor is a sensor resistor that changes resistance as temperature changes. It is classified into positive temperature coefficient thermistor (PTC thermistor) and negative temperature coefficient thermistor (NTC thermistor) based on various temperature coefficients (NTC thermistor). The resistance value of the PTC thermistor increases as the temperature rises, while the resistance value of the NTC thermistor lowers as the temperature rises, both of which are semiconductor devices.

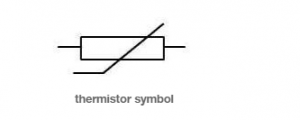

Thermistor Symbol

thermistor symbol

Types of Thermistor

In the following part, Easybom will give a brief introduction to thermistor classifications.

1. PTC thermistor

PTC thermistor refers to a thermistor with a material with a positive temperature coefficient that increases sharply in resistance at a certain temperature and can be used exclusively as a constant temperature sensor.

Experiments show that in the working temperature range, the resistance-temperature characteristics of PTC thermistors can be approximated by the experimental formula:

R(T)=R(T0)*exp(Bp(T-T0))

In the formula, R(T) and R(T0) represent the resistance value when the temperature is T and T0, and Bp is the material constant of the material.

The PTC effect originates from the properties of the precipitates between grain boundaries and changes significantly with the type, concentration, and sintering conditions of impurities. Recently, the silicon wafer has been used in temperature-sensitive elements, which forms the PTC thermistor with a small size and high precision. It is composed of n-type silicon, and electron scattering due to impurities therein increases with the increase of the temperature, thus the resistance increases.

PTC thermistors can be used for temperature measurement and control in industry, as well as for temperature detection and adjustment of certain parts of automobiles. It is also widely used in civil equipment, such as controlling the water temperature of the instantaneous water heater, and the temperature of the air conditioner and the cold storage, as well as the application of heating and overheating protection to heaters, motors, transformers, high-power transistors, and other electrical appliances.

In addition to being used as a heating element, the PTC thermistor can also play the role of a “switch”, which has three functions of a sensitive element, a heater, and a switch, which is called a “thermal switch”. After the current passes through the element, the temperature rises, that is, the temperature of the heating element rises. When the temperature exceeds the Curie point, the resistance increases, thereby limiting the increase of the current. Therefore, the decrease of the current causes the temperature of the element to decrease, and the decrease of the resistance value makes the circuit current increase, the temperature of the component rises, and this process is repeated, so it has the function of keeping the temperature in a specific range, and it also acts as a switch. Using this temperature resistance characteristic to make a heating source. It is used as a heating element in air heaters, electric soldering irons, drying cabinets, air conditioners, etc., and it can also protect electrical appliances from overheating.

2. NTC thermistor

NTC thermistor refers to the thermistor using the material whose resistance decreases exponentially with increasing temperature and has a negative temperature coefficient.

NTC thermal semiconducting ceramics are mostly oxide ceramics with spinel structure or other structures, with negative temperature coefficient, and the resistance value can be approximately expressed as:

R(T) = R(T0) *exp(Bn(1/T-1/T0))

where R(T) and R(T0) are the resistance values at temperatures T and T0, respectively, and Bn is the material constant. The resistivity of the ceramic grain itself changes due to temperature changes, which are determined by the characteristics of the semiconductor.

The development of NTC thermistors has gone through a long period of time. In 1834, scientists first discovered that silver sulfide has a negative temperature coefficient. In 1930, scientists discovered that cuprous oxide-copper oxide also has the performance of negative temperature coefficient, and successfully used it in the temperature compensation circuit of aviation instruments. Subsequently, due to the continuous development of transistor technology, the research of thermistors has made significant progress. The NTC thermistor was developed in 1960 and has been widely used in temperature measurement, temperature control, temperature compensation, and so on.

What does a thermistor do?

In the following part, Easybom will give a brief introduction to thermistor applications.

The most important application of the thermistor is as a temperature detection element, and an NTC thermistor is usually used for temperature detection. For example, it is commonly used in household appliances, such as rice cookers, induction cookers, etc.

- Over-temperature alarm circuit

The picture above is an over-temperature alarm circuit composed of a thermistor as a temperature detection element.

Its working principle is: when the environment or the detected temperature is low, the resistance value of the thermistor RT is high, at this time the input terminal of the logic gate IC-1 is high level, and it is low after IC-1 inversion. At this time, the base of the transistor VT1 is at a low level, VT1 is turned off, and the relay does not operate; after the IC-2 inversion, the output is at a high level, and the LED does not emit light; the input terminal of IC-3 is at a low level. The oscillator circuit composed of -3 and IC-4 does not work, and the speaker has no sound output.

When the temperature rises, the resistance of RT decreases. When the temperature rises to a certain value, the input terminal of IC-1 becomes low level and outputs a high level after inversion. At this time, the base of triode VT1 is high level, the triode is turned on, the relay coil is energized, and the load behind it is controlled; after the IC2 is inverted, the output is low, and the LED lights up; the input of IC-3 is high, the oscillator works, and the speaker gives a sound alarm.

In addition to being used as a temperature detection element, thermistors have the following applications.

- Application of NTC thermistor in switching power supply

The switching power supply is the working process of AC-DC-AC-DC. After the alternating current is rectified, it will be filtered by the capacitor. At the moment of power-on, because the capacitor needs to be charged, the instantaneous current will be much larger than that during normal operation, which will affect the rectifier part in the front, the fuse, and the power grid. Usually, an NTC thermistor is connected in series with the input end of the switching power supply. Since it has a high resistance at room temperature, it will play a certain current limiting effect at the moment of power-on. The current will cause the NTC thermistor to heat up. As the temperature increases, its resistance value will decrease. At this time, it is equivalent to a wire to ensure the normal operation of the power supply.

- PTC degaussing resistor

Old-fashioned picture tube (CRT) televisions display images by changing the direction of electron beam movement through an electromagnetic field. Affected by the environmental magnetic field or geomagnetism, the electron beam will be deflected, which will affect the displayed image and color. When the TV is turned on, the picture tube needs to be degaussed. The degaussing coil is surrounded by the picture tube, and the purpose of degaussing can be achieved by connecting the power frequency alternating current, and the process of degaussing only needs to be at the moment of power-on.

By connecting PTC in the degaussing circuit, the purpose of automatic power off after degaussing can be achieved. Due to the small resistance value of PTC at normal temperature, the alternating current will supply power to the degaussing coil through the degaussing resistor, and the current flowing will make the temperature of the degaussing resistor rise. The current of the degaussing circuit decreases, causing the degaussing coil to stop working.

- PTC heating plate

Traditional electric heating generally uses tungsten wire as the heating material, but its life is short and the anti-vibration ability is weak. Many household appliances, such as heaters and electric auxiliary heating of air conditioners, use PTC as heating material. The service life of PTC is much longer than that of tungsten wire, and as the heating temperature increases, the resistance value of PTC will also increase, and its operating current will gradually decrease. When the temperature drops, the resistance value will decrease and the current will increase, thus playing a certain purpose of automatic constant temperature.

What are the differences between thermistors and thermocouples?

Thermistor vs thermocouple

Thermocouple: A closed-loop formed by connecting two different metals in series. When the temperature of the two junctions is different, a thermoelectric potential can be generated in the circuit. This phenomenon is called the thermoelectric effect. A temperature sensor made using the thermoelectric effect is a thermocouple.

Thermistor: A sensitive element made of semiconductor material, which is characterized by a significant change in resistance value with temperature. It can directly convert changes in temperature into changes in electricity.

Both thermocouples and thermistors are temperature sensors. The main differences are:

1. Nature of the signal

The thermistor itself is a resistor and its resistance changes with temperature changes (positive or negative resistance changes). The thermocouple’s induced voltage is different with different temperatures.

2. Detected temperature range

The thermistor generally detects the temperature range of -50~150℃, so the thermistor is generally only used for low-temperature detection; the detection temperature range of the thermocouple is 0~2400℃, so the thermocouple is generally used for high-temperature detection.

3. Production materials

A thermistor is a metallic material (a metallic material with temperature-sensitive changes). Thermocouples, on the other hand, are bimetallic (ie, two different metals).

How to test a thermistor?

In the following part, Easybom will talk about how to test a thermistor.

The heating method can be used to detect the quality of the thermistor as shown in the figure. Use the two test pens of the multimeter to connect the two leads of the thermistor, and then use a hot electric soldering iron (20W) to heat the thermistor (close to the thermistor). For PTC thermistors, as the temperature increases, the resistance value should increase; for NTC thermistors, as the temperature increases, the resistance value should decrease. If the thermistor is heated and its resistance does not change, the thermistor is damaged.

Detection of PTC thermistor

When testing, use the multimeter R×1 block, which can be operated in two steps:

- Normal temperature detection (indoor temperature is close to 25°C): Measure the actual resistance value by connecting the two test pens with the two pins of the PTC thermistor, and comparing it with the nominal resistance value. The difference between the two is within ±2Ω, which is normal. . If the actual resistance value is too different from the nominal resistance value, it means that its performance is poor or damaged.

- Heating detection: On the basis of the normal temperature test, the second step test – heating detection can be carried out, a heat source (such as an electric soldering iron) is heated near the PTC thermistor. Use a multimeter to monitor whether the resistance value increases with the increase of temperature. If so, it means that the thermistor is normal; if there is no change in the resistance value, it means that its performance has deteriorated and cannot be used continuously. Be careful not to place the heat source too close to the PTC thermistor or contact the thermistor directly to prevent burning it.

Detection of NTC thermistor

- Measure the nominal resistance value Rt: The method of measuring the NTC thermistor with a multimeter is the same as the method of measuring the ordinary fixed resistor, that is, selecting the appropriate electrical barrier according to the nominal resistance value of the NTC thermistor can directly measure the actual value of Rt. However, because NTC thermistors are very sensitive to temperature, the following points should be paid attention to when testing: A. Rt is measured by the manufacturer when the ambient temperature is 25°C, so when measuring Rt with a multimeter, the ambient temperature should also be close to 25°C to ensure the reliability of the test. B. The measurement power should not exceed the specified value, so as to avoid measurement errors caused by the thermal effect of the current. C. Pay attention to correct operation. When testing, do not pinch the thermistor with your hands to prevent human body temperature from affecting the test.

- Estimate the temperature coefficient αt: first measure the resistance value Rt1 at room temperature t1, then use an electric soldering iron as a heat source to approach the thermistor Rt to measure the resistance value RT2. At the same time, use a thermometer to measure the average temperature of the surface of the thermistor RT.

Also read How To Make Your Fireworks Event Safe And Successful